Electric Hammer Drill Bit Stuck: Causes, Solutions, and Brand-Specific Insights

Electric hammer drills are indispensable tools in construction, renovation, and DIY projects, valued for their ability to bore through tough materials like concrete, brick, and stone. However, a common and frustrating issue users face is a stuck drill bit—when the bit refuses to detach from the chuck, halting work and potentially damaging the tool if mishandled. This comprehensive guide explores the reasons behind stuck drill bits, step-by-step solutions to resolve the issue, and detailed insights into popular electric hammer drill brands and models, highlighting their unique features that may influence bit retention and removal.

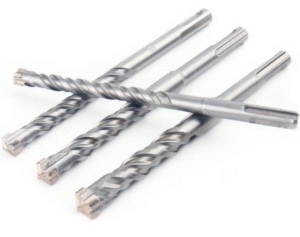

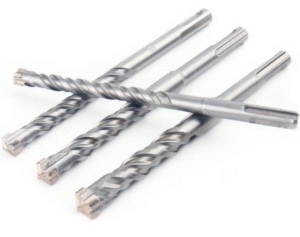

Before delving into stuck bits, it is critical to understand the role of the chuck—the part of the drill that holds the bit in place. Electric hammer drills typically use specialized chucks designed to withstand high-impact forces, with the most common types being SDS (Slotted Drive System) chucks, including SDS-plus, SDS-max, and SDS-top. These systems use spring-loaded balls or pins that lock into grooves on the drill bit, ensuring a secure fit during high-torque and hammering operations. Unlike traditional keyed or keyless chucks found on regular drills, SDS chucks rely on a push-and-twist mechanism for bit insertion and removal, which, while efficient, can become problematic if not maintained or used correctly.

Other chuck types include keyless chucks (common in lighter-duty hammer drills) and keyed chucks (found in older or heavy-duty models), but SDS systems dominate professional-grade tools due to their superior grip and quick-change capabilities. The design of the chuck directly impacts how easily bits can become stuck; for example, SDS chucks with worn springs or misaligned locking mechanisms are far more prone to jamming than well-maintained ones.

A drill bit can become stuck for various reasons, ranging from user error to mechanical wear. Identifying the root cause is essential for safe and effective removal. Below are the most prevalent factors:

-

Debris Buildup in the Chuck

During operation, dust, concrete particles, and metal shavings often accumulate in the chuck’s crevices, especially when drilling through porous or dusty materials like concrete. Over time, this debris can clog the locking mechanism, preventing the spring-loaded balls or pins from retracting properly. In SDS chucks, debris may wedge between the bit’s grooves and the chuck’s locking components, creating a tight seal that resists removal. This issue is particularly common in models used in dusty environments without proper cleaning routines, such as the Bosch GBH 2-28 DRE, which, while durable, requires regular maintenance to prevent debris buildup.

-

Worn or Damaged Chuck Components

The springs, balls, or pins in the chuck are subject to constant stress during use. Over time, springs can lose tension, and locking balls may become worn or misaligned, leading to an inconsistent grip. When a spring fails to retract fully, it may keep the locking mechanism engaged even when the release button is pressed, trapping the bit. This is a frequent issue in older models or those used heavily without maintenance, such as the DeWalt D25414K, a workhorse in construction but prone to chuck wear after years of intensive use.

-

Incorrect Bit Installation

User error is a significant contributor to stuck bits. SDS bits must be inserted fully into the chuck until they “click” into place, ensuring the locking mechanism engages properly. If a bit is only partially inserted, the locking components may not align correctly, causing the bit to jam when pressure is applied during drilling. Similarly, using a bit that is incompatible with the chuck type (e.g., an SDS-plus bit in an SDS-max chuck) can lead to misalignment and jamming. Models like the Makita HR2630, which uses an SDS-plus system, require precise bit insertion to avoid such issues.

-

Overheating and Material Welding

Extended drilling sessions, especially through hard materials like reinforced concrete, generate significant friction and heat. In extreme cases, this heat can cause metal particles from the bit and chuck to fuse (a phenomenon known as “welding”), creating a permanent bond. This is more likely in low-quality drills with poor heat dissipation, such as budget models from brands like Black+Decker, which may lack the robust cooling systems found in professional tools like the Milwaukee 2804-20.

-

Rust and Corrosion

Moisture exposure can lead to rust in the chuck, particularly if the tool is stored in damp environments or used outdoors without protection. Rust causes metal components to seize, making it nearly impossible to release the bit. This issue is common in entry-level models like the Ryobi R18HDD-0, which may have less corrosion-resistant materials compared to premium brands.

-

Bit Damage

A bent, warped, or cracked drill bit can become misaligned in the chuck, preventing the locking mechanism from releasing. When a bit is damaged during use (e.g., hitting rebar in concrete), it may shift position, jamming against the chuck walls. This is a frequent problem with low-quality bits used in high-powered drills like the Hitachi DH36DPA, where excessive force exacerbates bit wear.

Removing a stuck drill bit requires patience, the right tools, and a systematic approach to avoid damaging the drill or injuring oneself. Below is a detailed guide to resolving the issue safely:

Before attempting any removal, disconnect the drill from its power source (unplug corded models or remove the battery from cordless ones). This prevents accidental activation during the process, which could cause serious injury. Wear protective gloves to avoid cuts from sharp metal edges and safety glasses to shield against flying debris.

Examine the chuck for visible debris, rust, or damage. Use a flashlight to check for dust, concrete particles, or metal shavings clogging the locking mechanism. If debris is visible, use a compressed air canister or a small brush (like a toothbrush) to gently dislodge it. For SDS chucks, focus on the slots where the locking balls engage with the bit—debris here is a common culprit.

If debris removal alone doesn’t work, apply a penetrating lubricant (such as WD-40, PB Blaster, or a specialized metal lubricant) to the chuck. Spray or 滴几滴 lubricant around the base of the bit where it meets the chuck, allowing it to seep into the gaps for 10–15 minutes. Lubrication helps dissolve rust, reduce friction, and loosen stuck components. For stubborn cases, repeat the process and let the lubricant sit longer, up to an hour.

Most electric hammer drills have a chuck release button or lever, typically located near the base of the chuck. For SDS chucks, pressing this button should retract the locking balls, allowing the bit to be pulled out. If the button is stuck, gently tap it with a rubber mallet to free it—avoid using excessive force, as this can damage the button’s spring. For keyless chucks, twist the collar counterclockwise while pressing the release button (if equipped).

If the bit remains stuck, grip the bit firmly with a pair of pliers (preferably with rubber-coated jaws to avoid damaging the bit) and pull straight out while pressing the release button. For SDS bits, a slight twist (clockwise or counterclockwise) may help align the grooves with the locking balls, easing removal. Never yank or bend the bit, as this can warp it or damage the chuck.

For severely stuck bits, lightly tap the end of the bit with a rubber mallet while pulling. The vibrations can dislodge debris or break rust bonds. Alternatively, tap the side of the chuck (near the base) to loosen the locking mechanism. Be cautious not to hit the drill’s motor housing or other delicate components.

If all else fails, disassembling the chuck may be required. This step is recommended only for experienced users, as it involves removing screws, springs, and small parts that can be easily lost. Refer to the drill’s user manual for disassembly instructions specific to your model. For example, the Bosch GBH 5-40 D requires removing a retaining ring before accessing the chuck’s internal components, while the Makita HR4040C uses a screw-on chuck that can be unscrewed with a specialized tool. Once disassembled, clean each part thoroughly, replace worn components (e.g., springs, balls), and reassemble carefully.

If DIY methods fail, or if you are uncomfortable disassembling the tool, contact the manufacturer’s service center or a certified repair technician. Attempting forced removal without expertise can lead to irreparable damage to the chuck, motor, or other critical parts, especially in high-end models like the Milwaukee 2917-20, where precision components are costly to replace.

Different brands and models feature unique chuck designs, build quality, and maintenance requirements, all of which influence the likelihood of stuck drill bits. Below is a detailed overview of leading brands and their key models:

Bosch is a German manufacturer renowned for durable, professional-grade power tools. Their electric hammer drills are widely used in construction and masonry work, with a focus on ergonomic design and reliable performance.

-

Model: Bosch GBH 2-28 DRE

This is a versatile SDS-plus hammer drill designed for medium-duty applications, including drilling in concrete, brick, and stone. It features a 800-watt motor, variable speed control, and a rotating brush plate for consistent power in both forward and reverse. The chuck uses Bosch’s Auto-Lock SDS-plus system, which allows for quick bit changes with a simple push-and-twist motion. While the Auto-Lock mechanism is generally reliable, debris buildup in the chuck’s slots is a common issue, especially in dusty environments. Regular cleaning with compressed air and occasional lubrication with Bosch’s recommended grease (part number 2607000566) can prevent jams. Users report that the chuck release button is sturdy but may require firm pressure if debris is present.

-

Model: Bosch GBH 5-40 D

A heavy-duty SDS-max hammer drill, the GBH 5-40 D is built for large-scale projects, such as drilling anchor holes in reinforced concrete. Its 1,500-watt motor delivers high impact energy (4.0 J), and the chuck features a SDS-max quick-change system with reinforced locking balls to handle large bits. The chuck is more robust than SDS-plus models but is still prone to wear over time, particularly if used with damaged bits. The release lever is larger and easier to operate than buttons on smaller models, reducing the risk of user error during bit changes. However, the SDS-max system’s larger size means more debris can accumulate in the grooves, making regular maintenance critical.

DeWalt, a subsidiary of Stanley Black & Decker, is a favorite among professionals for its rugged tools and innovative features. Their electric hammer drills are designed for durability and high performance in demanding worksites.

-

Model: DeWalt D25414K

This SDS-plus hammer drill kit includes a 7.5-amp motor, a 3-mode selector (drill, hammer drill, and chisel), and a keyless SDS-plus chuck for tool-free bit changes. The chuck uses a spring-loaded mechanism with hardened steel balls to secure bits, and it features a rubberized grip on the release button for comfort. Users praise its quick bit changes but note that the chuck can become stiff if not cleaned regularly. The D25414K is prone to debris buildup in the chuck’s collar, especially when drilling through drywall or concrete dust. DeWalt recommends using compressed air to clean the chuck after each use and applying a light machine oil to the locking mechanism every 50 hours of operation.

-

Model: DeWalt DCH273B

A cordless SDS-plus hammer drill powered by a 20V MAX battery, the DCH273B is popular for its portability and performance. It features a brushless motor for longer runtime and a Compact SDS-plus Chuck designed to reduce weight and improve balance. The chuck’s release button is integrated into the collar, requiring a twist-and-press motion for bit removal. While the compact design is ergonomic, it leaves less space for debris to escape, increasing the risk of jams. Users advise avoiding over-tightening the bit during insertion, as this can cause the locking balls to dig into the bit’s grooves, making removal harder.

Makita, a Japanese brand, is known for its precision engineering and long-lasting tools. Their electric hammer drills are celebrated for low vibration, high efficiency, and user-friendly designs.

-

Model: Makita HR2630

This SDS-plus hammer drill is a mid-range model with a 710-watt motor, ideal for DIY enthusiasts and professionals alike. It features a Quick Change Chuck system that allows for one-handed bit insertion and removal, reducing downtime. The chuck uses a spring-loaded pin mechanism that engages with the bit’s grooves, and it includes a dust seal to minimize debris intrusion. However, the dust seal can wear over time, allowing particles to enter the chuck—regular inspection and replacement of the seal (part number 211888-6) is essential to prevent jams. Users report that the HR2630’s chuck is less prone to sticking than budget models but still requires lubrication with Makita’s special grease (part number 186897-2) every few months.

-

Model: Makita HR4040C

A heavy-duty SDS-max hammer drill, the HR4040C is designed for industrial use, with a 1,400-watt motor and a maximum impact energy of 6.7 J. Its chuck features a Super Joint System that reduces vibration and a reinforced locking mechanism to handle large SDS-max bits. The chuck release lever is positioned for easy access, even when wearing gloves, and the internal components are made from high-grade steel to resist wear. While highly durable, the HR4040C’s chuck can become stuck if bits are not fully inserted—users must ensure they hear a “click” before starting work. Makita recommends cleaning the chuck with a wire brush and applying lubricant after use in dusty conditions.

Hitachi, rebranded as Metabo HPT, offers a range of reliable hammer drills with a focus on value and performance. Their tools are popular among contractors and homeowners seeking a balance between quality and affordability.

-

Model: Metabo HPT DH36DPA

A cordless SDS-plus hammer drill powered by a 36V battery, the DH36DPA delivers high power (2.1 J impact energy) for heavy-duty tasks. It features a Tool-less Chuck Change system with a large release button, making bit changes quick and easy. The chuck is designed with a dust cover to protect internal components, but users note that the cover can trap small debris if not cleaned regularly. The locking balls are made from hardened steel, but over time, they may develop burrs from use with low-quality bits, leading to jams. Metabo HPT recommends using only genuine SDS-plus bits and inspecting the chuck for wear every 100 hours of operation.

-

Model: Metabo HPT DH26PBD

A corded SDS-plus hammer drill with a 7.0-amp motor, the DH26PBD is a budget-friendly option for light to medium-duty work. Its chuck uses a basic SDS-plus mechanism with a simple release button, and while it lacks the advanced dust seals of premium models, it is easy to maintain. Users report that this model is prone to stuck bits if used in dusty environments, as debris easily enters the chuck. Regular cleaning with a cloth and application of general-purpose lubricant can mitigate this issue, though it may not be as effective as the specialized greases used in higher-end models.

Milwaukee Tool is known for its innovative, professional-grade tools, often featuring advanced technology to enhance performance and durability. Their electric hammer drills are designed for heavy use in harsh conditions.

-

Model: Milwaukee 2804-20

A cordless SDS-plus hammer drill in Milwaukee’s M18 Fuel line, the 2804-20 uses a brushless motor and RED LITHIUM batteries for long runtime. It features a Auto-Lock SDS-plus Chuck with a reinforced release button that withstands rough handling. The chuck includes a built-in dust extraction port that can be connected to a vacuum, significantly reducing debris buildup—a key advantage in preventing stuck bits. Users praise this feature, noting that it reduces maintenance needs compared to models without dust extraction. The locking mechanism uses high-strength steel balls, and Milwaukee recommends using their M18 Lubricant (part number 48-11-1820) to keep the chuck functioning smoothly.

-

Model: Milwaukee 2917-20

This SDS-max hammer drill is part of Milwaukee’s high-performance lineup, designed for industrial drilling and chiseling. It features a 1,500-watt motor, REDLINK PLUS intelligence to prevent overheating, and a Heavy-Duty SDS-max Chuck with oversized locking balls for secure bit retention. The chuck’s release lever is reinforced with a rubber grip for easy operation, even in wet or dirty conditions. The 2917-20 includes a debris shield that covers the chuck’s openings, minimizing dust intrusion. While highly resistant to jams, improper bit insertion (e.g., using a bent bit) can still cause sticking—Milwaukee advises users to inspect bits for damage before each use.

Black+Decker is a household name in DIY tools, offering affordable, user-friendly options for homeowners and occasional users. Their hammer drills are designed for light to medium-duty tasks.

-

Model: Black+Decker BDCH220B

A cordless SDS-plus hammer drill powered by a 20V battery, the BDCH220B is aimed at DIYers and homeowners. It features a simple chuck design with a release button and basic locking mechanism. While easy to use, the chuck lacks advanced dust protection, making it prone to debris buildup. Users report that stuck bits are common if the tool is used without regular cleaning, especially in concrete drilling. Black+Decker recommends wiping the chuck with a dry cloth after use and applying a small amount of lubricating oil to the release mechanism monthly.

-

Model: Black+Decker KR705K

A keyed chuck hammer drill (not SDS), the KR705K is a budget option for drilling in wood, metal, and soft masonry. Its keyed chuck requires a separate key for tightening and loosening bits, which can become lost or damaged. Stuck bits in this model often result from over-tightening with the key or debris in the chuck’s teeth. Users should avoid forcing the key when loosening the chuck, as this can strip the teeth, and clean the chuck regularly with a brush to remove dust and shavings.

Preventing stuck bits is far easier than resolving them, and regular maintenance can extend the life of your electric hammer drill while ensuring smooth operation. Below are key preventive steps:

-

Clean the Chuck Regularly

After each use, especially in dusty environments, clean the chuck with compressed air or a brush to remove debris. For SDS chucks, focus on the slots where the locking balls engage—even small particles can cause jams. For keyed or keyless chucks, wipe the internal teeth with a cloth to prevent dust buildup.

-

Lubricate the Chuck Mechanism

Apply a specialized lubricant or grease (recommended by the manufacturer) to the chuck’s moving parts every 50–100 hours of use. SDS chucks benefit from grease applied to the locking balls and springs, while keyless chucks require lubrication in the collar’s threads. Avoid using household oils, as they can attract dust and cause buildup.

-

Use High-Quality, Compatible Bits

Always use drill bits designed for your chuck type (e.g., SDS-plus bits for SDS-plus chucks) and from reputable brands like Bosch, DeWalt, or Makita. Low-quality bits are more likely to bend, warp, or develop burrs, which can jam the chuck. Inspect bits for damage before use—discard any that are bent, cracked, or worn.

-

Insert Bits Correctly

Ensure bits are fully inserted into the chuck until they click into place, confirming the locking mechanism has engaged. For SDS bits, avoid partial insertion, as this misaligns the grooves and increases the risk of jamming. For keyed chucks, tighten the key firmly but not excessively to prevent over-tightening.

-

Avoid Overheating

Take breaks during extended drilling sessions to allow the tool and bit to cool. Overheating can cause metal components to expand and fuse, leading to stuck bits. If the drill feels hot to the touch, stop using it and let it cool for 10–15 minutes before resuming.

-

Store the Tool Properly

Store the drill in a dry, clean environment to prevent rust and corrosion. Use a carrying case or toolbox to protect it from moisture and dust when not in use. For long-term storage, apply a light coat of lubricant to the chuck and remove the battery (for cordless models) to prevent leakage.

-

Inspect and Replace Worn Components

Regularly check the chuck for signs of wear, such as loose locking balls, weak springs, or damaged release buttons. Replace worn parts promptly using genuine manufacturer replacements—using off-brand components can compromise performance and increase the risk of jams.

A stuck drill bit in an electric hammer drill is a common issue, but with proper understanding, maintenance, and troubleshooting, it can be resolved safely and effectively. By recognizing the causes—such as debris buildup, worn components, or user error—and following systematic removal steps, users can avoid tool damage and resume work quickly.

The choice of electric hammer drill brand and model also plays a significant role, as designs vary in terms of chuck durability, dust protection, and ease of maintenance. Brands like Bosch, DeWalt, Makita, Milwaukee, and Metabo HPT offer reliable options, each with unique features that influence bit retention and removal. By selecting a model suited to your needs, practicing regular maintenance, and using proper techniques, you can minimize the risk of stuck bits and ensure your electric hammer drill remains a reliable tool for years to come.

Remember, patience and care are key when dealing with a stuck bit—forced removal can lead to costly repairs, while a methodical approach will often resolve the issue without incident. With the insights provided in this guide, you are well-equipped to tackle stuck drill bits and keep your electric hammer drill operating at its best.