Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

How to Install the Drill Bit of the Impact Drill

Installing the drill bit of an impact drill may seem like a simple task, but in reality, it involves a careful sequence of steps that ensures safety, efficiency, and longevity of both the drill and the drill bit itself. Impact drills are powerful tools that are commonly used in construction, woodworking, metalworking, masonry, and home renovation projects. Unlike ordinary drills, an impact drill is designed to deliver not only rotational force but also a hammering action that makes it capable of penetrating tough materials such as concrete, stone, and metal. Because of this, installing the drill bit correctly is critical to ensure that the tool operates at its full potential without damaging the bit or the chuck mechanism. In this comprehensive guide, I will provide a detailed explanation of how to install the drill bit of an impact drill, what types of chucks are typically found in different brands and models, what safety measures to take, and what common mistakes to avoid. I will also introduce some of the leading impact drill brands in the market today such as Bosch, Makita, DeWalt, Hilti, Milwaukee, and Black+Decker, describing the models they offer and how their chuck systems are designed for ease of use. This text will provide not only practical instructions but also an in-depth exploration of the role that drill bit installation plays in ensuring optimal performance.

Understanding the Structure of the Impact Drill and Drill Bits

Before diving into the installation process, it is necessary to understand the main components of an impact drill and how the drill bit interacts with these components. The key part of an impact drill that holds the drill bit is called the chuck. The chuck can either be a keyless chuck, which allows the user to tighten or loosen it by hand, or a keyed chuck, which requires the use of a special tool called a chuck key. Drill bits for impact drills come in a variety of shank designs such as round shank, hex shank, and SDS shank, each designed to fit specific chuck types. For example, SDS drill bits are used in SDS rotary hammers and impact drills that support this system, while standard hex shank drill bits are common in cordless impact drills. Brands like Bosch and Hilti often use SDS-Plus or SDS-Max systems in their professional-grade models, whereas Makita, DeWalt, and Milwaukee also produce impact drills with quick-change chucks that accept hex bits. Understanding this compatibility is important because inserting the wrong type of drill bit may lead to slippage, reduced efficiency, or damage to the tool.

Step-by-Step Guide to Installing a Drill Bit in an Impact Drill

The installation process differs slightly depending on whether the drill uses a keyless chuck or a keyed chuck, but the general principle remains the same. Below is a step-by-step guide:

Ensure the Drill is Powered Off and Safe

Before handling the drill, make sure it is completely turned off. For corded drills, unplug the power cord from the outlet. For cordless drills, remove the battery pack. This precaution is critical because accidental pressing of the trigger can cause the chuck to rotate at high speed, which can result in injury.

Identify the Chuck Type

Determine whether the drill has a keyless chuck or a keyed chuck. Most modern cordless impact drills from brands such as DeWalt DCD996, Makita XPH14Z, and Milwaukee M18 Fuel 2804-20 feature keyless chucks, while some heavy-duty corded drills from Bosch or Hilti may still include keyed chucks for maximum grip.

Open the Chuck

If the drill has a keyless chuck, rotate the chuck sleeve counterclockwise to open the jaws wide enough to accept the drill bit. For a keyed chuck, insert the chuck key into the hole on the chuck, turn it counterclockwise, and expand the jaws.

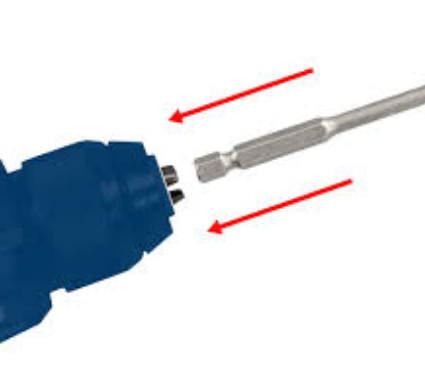

Insert the Drill Bit

Place the drill bit shank into the center of the chuck jaws. Ensure that the bit is straight and properly aligned. Push it in as far as it will go, but do not let the fluted part of the drill bit be clamped inside the jaws—only the smooth shank should be held.

Tighten the Chuck

For a keyless chuck, hold the base of the chuck with one hand and rotate the sleeve clockwise with the other hand until the jaws clamp tightly onto the bit. You should feel resistance as the chuck locks the bit in place. For a keyed chuck, insert the chuck key into the holes and turn it clockwise until the jaws firmly grip the bit. It is advisable to tighten all three holes if the chuck has them, ensuring even clamping force.

Test the Installation

Once tightened, gently pull on the drill bit to ensure it is securely held in place. The bit should not wobble or slide out. After this check, reinstall the battery or plug in the drill, then briefly press the trigger to confirm the bit spins straight without shaking.

Popular Impact Drill Brands and Their Drill Bit Installation Systems

When discussing drill bit installation, it is helpful to explore how different brands and models approach chuck design and user convenience.

Bosch: Bosch is well known for its SDS system, which is extremely popular in Europe and worldwide for masonry and concrete drilling. Models such as the Bosch GBH2-28L use the SDS-Plus chuck, which allows bits to be installed quickly without tightening jaws manually. Instead, the user simply inserts the SDS bit into the chuck until it clicks. This makes installation faster and more secure.

DeWalt: DeWalt’s DCD996 and DCD985 impact drills feature ½-inch keyless ratcheting chucks that grip drill bits tightly without slipping. Their design focuses on convenience for professional contractors who need to change bits frequently during work.

Makita: Makita’s XPH14Z cordless hammer drill includes a heavy-duty metal keyless chuck that allows smooth tightening and loosening. The precision engineering of Makita chucks ensures that drill bits are held firmly, reducing wobbling and enhancing drilling accuracy.

Milwaukee: Milwaukee’s M18 Fuel series, such as the 2804-20, uses a durable ½-inch all-metal chuck with a ratcheting lock system. This ensures drill bits do not loosen under heavy loads, which is essential in demanding industrial tasks.

Hilti: Hilti drills like the TE 7-C use advanced SDS-Plus chucks for fast insertion and removal of bits. The SDS system eliminates the need for a chuck key, making Hilti tools extremely efficient for masonry and construction professionals.

Black+Decker: For home use and DIY projects, Black+Decker offers affordable impact drills such as the BDCI20C, which feature ¼-inch hex quick-change chucks. These allow bits to be swapped with just one hand, ideal for light-duty tasks.

Safety Considerations When Installing Drill Bits

Installing a drill bit is not just about convenience but also about safety. Users should always wear protective gloves when handling drill bits, especially masonry or metal bits that have sharp edges. Eye protection is also essential in case small debris is dislodged during test spinning. Another important precaution is to ensure the chuck is tightened fully, because a loosely installed bit can fly out during operation, causing severe injury.

Common Mistakes to Avoid

Several mistakes can compromise the performance of an impact drill. One common mistake is clamping the fluted cutting part of the drill bit instead of the shank, which can damage the bit and reduce cutting efficiency. Another mistake is failing to fully tighten the chuck, which results in slippage. Using the wrong type of bit for the chuck system, such as inserting a standard round shank into an SDS chuck, is another frequent error that can damage the chuck.

Maintenance of the Chuck and Drill Bits

Proper maintenance is also critical. The chuck should be kept clean and free from dust, especially in construction environments where concrete particles may accumulate. Applying a small amount of machine oil to the chuck mechanism can extend its lifespan. Drill bits themselves should also be inspected regularly for wear and replaced when dull, as using a worn bit puts unnecessary stress on both the drill and the chuck.

Conclusion

Installing the drill bit of an impact drill is a fundamental yet essential process that ensures efficient and safe operation of the tool. While the steps are straightforward, the nuances of different chuck types, brand designs, and safety considerations make it necessary to understand the details. Leading manufacturers such as Bosch, Makita, DeWalt, Milwaukee, Hilti, and Black+Decker all provide different chuck systems tailored to their target users, whether professional contractors or home DIY enthusiasts. By following the proper installation steps, using the right bit type, and maintaining the chuck system, users can maximize the performance of their impact drills and avoid common pitfalls.