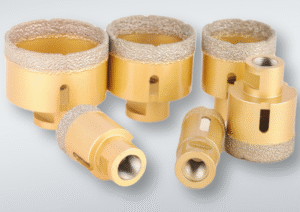

Brazing hole saws are essential tools in various industries, including construction, woodworking, and metalworking. They are designed to cut precise holes in different materials, such as wood, plastic, and metal. In this comprehensive guide, we will explore the different models of brazing hole saws available in the market, along with their features, applications, and top brands.

Control the Cutting Speed

Using the correct cutting speed is crucial for both safety and the performance of the brazing hole saw. Different materials require different speeds to prevent overheating, which can damage the saw and create hazardous conditions like flying sparks or melted debris. Most drills, especially variable-speed models, have speed settings indicated in revolutions per minute (RPM). For soft materials such as wood or plastic, a moderate to high speed (around 1000-2500 RPM) is typically recommended to achieve a smooth cut without bogging down the drill. For metals, slower speeds are necessary: soft metals like aluminum may work well at 500-1000 RPM, while harder metals like stainless steel require even slower speeds (200-500 RPM) to reduce friction and heat buildup. Always refer to the drill and hole saw manufacturer’s guidelines for recommended speed settings to avoid accidents.

Use Cooling and Lubrication

When cutting metals, especially hard ones like steel or cast iron, heat can quickly build up in the hole saw, leading to dulling of the teeth or even warping of the saw body. To prevent this, using a cooling agent or lubricant is essential. Cutting oil is commonly used for metalworking; applying a few drops of oil to the cutting area before and during the cut helps dissipate heat and reduces friction between the saw teeth and the material. For larger or prolonged cuts, periodic pauses to reapply oil and allow the saw to cool down can extend the tool’s life and improve safety. In industrial settings, some operators use mist cooling systems that spray a fine mist of coolant directly onto the cutting zone, ensuring continuous cooling during high-volume operations.

Inspect Tools Before Use

Before starting any cutting task, thoroughly inspect the brazing hole saw and the drill for signs of damage. Check the saw teeth for cracks, chips, or excessive wear—damaged teeth can break off during cutting and become dangerous projectiles. Examine the arbor and its connection points to ensure they are secure and free from rust or debris that could cause slippage. For the drill, check the power cord (if corded) for fraying or damage, and ensure the chuck is functioning properly to grip the arbor tightly. If any defects are found, replace the damaged parts or the entire tool before use. A quick pre-use inspection can prevent tool failure and potential injuries.

Avoid Overloading the Drill

Overloading the drill by forcing it into the material can strain the motor, damage the drill’s gears, or cause the hole saw to bind. Let the saw do the work—apply steady, moderate pressure rather than excessive force. If the drill starts to slow down significantly, emit a burning smell, or vibrate excessively, stop immediately. This may indicate that the saw is dull, the speed is incorrect, or the material is too tough for the current tool. Continuing to force the drill in such situations can lead to overheating, which may cause the drill to malfunction or even start a fire. Forcing the saw can also result in an uneven cut or the saw getting stuck in the material, requiring extra effort to remove and increasing the risk of injury.

Clear the Work Area

Maintaining a clean and organized work area is an often-overlooked safety precaution. Before starting, remove any unnecessary tools, debris, or flammable materials from the vicinity of the cutting operation. Flying chips or sparks from metal cutting can ignite flammable substances like oil, paint, or sawdust, leading to fires. Keep a fire extinguisher nearby when working with metals, especially in industrial or garage settings. After cutting, promptly clean up the debris—wood chips, metal shavings, and plastic fragments—to prevent slips, trips, or accidental contact with sharp edges. A cluttered workspace increases the risk of accidents, so taking a few minutes to tidy up beforehand and afterward is well worth the effort.

Ryobi

-

Ryobi RAK08HS Hole Saw Kit

- Features: This budget-friendly kit is designed for DIY enthusiasts and occasional users, including 8 hole saws with diameters ranging from 3/4 inch to 2 1/2 inches. The saws are made of high-speed steel (HSS) with brazed teeth, offering decent durability for cutting wood, plastic, and thin metals like aluminum. The set includes a universal arbor that fits most standard drills, along with a pilot bit to ensure precise alignment. The teeth are designed with a staggered pattern to reduce clogging and improve chip removal, making cuts smoother even in fibrous materials like particleboard.

- Applications: Ideal for home improvement projects such as installing light fixtures, cutting holes for pipes in wooden studs, or creating openings for electrical outlets. It’s also suitable for hobbyists working on crafts involving wood or plastic, where accuracy and affordability are key priorities.

-

Ryobi Carbide-Tipped Hole Saws

- Features: For more demanding tasks, Ryobi offers carbide-tipped hole saws in sizes from 1 inch to 4 inches. The carbide tips are brazed onto a steel body, providing enhanced hardness for cutting through tough materials like stainless steel, cast iron, and hardwoods. These saws feature a reinforced body to withstand high torque, reducing the risk of bending or breaking during heavy use. They also include a special anti-corrosion coating to 延长使用寿命,even when exposed to moisture or cutting fluids.

- Applications: Perfect for professional users in metalworking or construction who need to cut through hard materials regularly. Examples include cutting holes in metal conduit for electrical installations, creating openings in cast iron pipes for plumbing repairs, or working with hardwoods like maple or walnut in furniture making.

Hitachi

-

Hitachi 725057 Hole Saw Set

- Features: This mid-range set includes 10 bi-metal hole saws, with diameters from 1/2 inch to 3 inches. The bi-metal construction combines HSS teeth for sharpness with a flexible steel body to resist breakage, making them versatile for cutting wood, plastic, and thin to medium-gauge metals. The arbor included in the set features a quick-release mechanism, allowing for fast and easy 更换 of hole saws without the need for additional tools. The teeth have a variable pitch design, which reduces vibration during cutting, resulting in cleaner cuts and less fatigue for the user.

- Applications: Suitable for both DIYers and professionals in fields like electrical work, where cutting through a mix of materials (wooden framing and metal boxes) is common. It’s also useful in automotive repair shops for cutting holes in metal panels or plastic components of vehicles.

-

Hitachi Variable-Speed Optimized Hole Saws

- Features: These hole saws are engineered to work seamlessly with variable-speed Hitachi drills, with tooth geometry optimized for different RPM ranges. They are available in sizes from 1 1/4 inches to 5 inches, with HSS blades for general use and carbide-tipped options for hard materials. The saws have a heat-resistant coating that dissipates heat effectively, even at high speeds, preventing premature dulling. The body is lightweight yet strong, making them easy to handle during extended use.

- Applications: Designed for users who frequently switch between materials, such as contractors working on mixed-material projects. For example, cutting holes in PVC pipes (low speed) and then switching to cutting through steel studs (higher torque, lower speed) without needing to change tools, thanks to the variable-speed compatibility.

Black+Decker

-

Black+Decker BDHT70013 Hole Saw Kit

- Features: This entry-level kit is perfect for beginners, including 6 HSS hole saws (sizes 3/4 inch to 2 inches) and a basic arbor. The saws are designed with simple, straight teeth brazed onto a steel body, offering reliable performance for cutting softwoods, plastics, and thin aluminum. The set comes in a compact storage case, keeping the saws organized and easy to transport. The pilot bit is integrated into the arbor, ensuring that even novice users can achieve straight, accurate holes without misalignment.

- Applications: Ideal for small home projects like installing doorknobs (cutting holes in wooden doors), creating openings for cable management in desks, or DIY crafts involving foam or lightweight plastics. Its affordability and ease of use make it a popular choice for those new to using hole saws.

-

Black+Decker Professional Bi-Metal Hole Saws

- Features: Targeting professional users, these bi-metal hole saws are available in larger sizes (up to 6 inches) and feature a thicker steel body for durability. The HSS teeth are brazed with high precision to ensure a strong bond, and they have a progressive tooth design that starts with larger gaps for fast chip removal and finishes with finer teeth for clean cuts. The arbors are compatible with most professional-grade drills, including cordless models, and include a locking mechanism to prevent slippage during high-torque operations.

- Applications: Used in commercial construction for cutting holes in metal studs, drywall, and plywood. They are also suitable for industrial maintenance tasks, such as cutting holes in machinery panels or metal enclosures for wiring or plumbing access.

Anti-Clogging Designs

Many modern brazing hole saws incorporate anti-clogging features to improve efficiency and safety. This includes enlarged gullets (the spaces between teeth) to allow for better chip evacuation, preventing debris from getting stuck and causing the saw to bind. Some models, especially those designed for woodworking, have slots along the body of the saw that allow chips to escape during cutting, reducing the need for frequent pauses to clear the saw. For example, Bosch’s “Clean Cut” series features strategically placed slots that channel sawdust away from the cutting area, maintaining consistent performance even during prolonged cuts in thick wood.

Shock-Absorbing Technology

High-end hole saws, particularly those used in industrial settings, often include shock-absorbing features to reduce vibration. Vibration not only causes user fatigue but can also damage the saw teeth and the drill over time. Brands like Milwaukee integrate rubber or polymer dampeners into the arbor or saw body, which absorb vibrations during cutting. This technology is especially beneficial when cutting hard materials like steel, where vibration levels are higher, as it improves user comfort and extends the tool’s lifespan.

Depth Markings

To help users achieve precise hole depths, some brazing hole saws are marked with depth indicators along the body. These markings, typically in inches or millimeters, allow operators to gauge how deep the saw has cut without stopping to measure, improving accuracy and reducing errors. This feature is particularly useful in applications where consistent hole depth is critical, such as installing recessed lighting fixtures (where the hole depth must match the fixture’s dimensions) or creating holes for bolts that need to sit flush with the material surface.

Corrosion Resistance

Given that hole saws are often used in environments where they may come into contact with moisture, cutting fluids, or humidity, corrosion resistance is a key feature in modern models. Many saws are coated with materials like black oxide, chrome, or ceramic to prevent rust and corrosion. For example, Dewalt’s “Tough Coat” finish forms a protective barrier on the steel body, ensuring the saw remains in good condition even after exposure to water or metalworking fluids, which is essential for long-term durability in professional settings.

Dull Teeth

One of the most common issues is dull teeth, which result in slow, uneven cuts and increased heat buildup. Dulling can occur due to cutting materials that are too hard for the saw type (e.g., using an HSS saw on stainless steel) or prolonged use without proper cooling. To address this, first, ensure you’re using the correct saw for the material—switch to a carbide-tipped saw for hard metals. For HSS saws, sharpening as outlined in the maintenance section can restore performance. If teeth are chipped or excessively worn, replacement is necessary to avoid safety risks.

Binding or Sticking

Binding happens when the hole saw gets stuck in the material, often due to clogging with chips, incorrect speed, or insufficient pressure. To resolve this, stop the drill immediately and clear any debris from the saw teeth using a brush or compressed air. Adjust the cutting speed to match the material—slower speeds for metals, faster for wood. Applying steady, even pressure (rather than forcing the saw) can also prevent binding. In severe cases, where the saw is completely stuck, reverse the drill’s direction slightly to loosen it before removing it from the hole.

Uneven or Tapered Holes

Uneven holes are typically caused by misalignment of the saw or a worn pilot bit. The pilot bit is responsible for guiding the saw straight; if it’s dull or bent, the saw may wander. Check the pilot bit for damage and replace it if necessary. Ensure the workpiece is securely clamped to prevent movement during cutting, as even slight shifts can lead to uneven holes. Using a drill with a built-in level or a guide attachment can also help maintain straight alignment, especially for larger holes where precision is critical.

Overheating

Overheating is evident by discoloration of the saw body (blueing) or a burning smell, and it can damage both the saw and the material. This issue is common when cutting metals without proper cooling or using speeds that are too high. To prevent overheating, use cutting oil or coolant for metal cuts, reduce the drill speed, and take frequent breaks to allow the saw to cool. If overheating occurs, stop cutting immediately, let the saw cool down, and inspect it for damage before resuming. Overheated HSS saws may lose their hardness, making them prone to dulling, so avoiding this issue is key to extending the tool’s life.

Brazing hole saws are versatile and essential tools across industries ranging from construction and metalworking to woodworking and DIY home improvement. Their design, which involves brazing sharp teeth (often HSS or carbide-tipped) onto a durable body, allows for precise hole cutting in a wide variety of materials. Understanding the different types—standard, bi-metal, arbor-type, and variable-speed—along with their features and applications, is crucial for selecting the right tool for the job.

Top brands like Bosch, Dewalt, Makita, Milwaukee, Ryobi, Hitachi, and Black+Decker offer a range of models tailored to different needs, from budget-friendly DIY kits to professional-grade carbide-tipped saws for tough materials. Proper maintenance, including sharpening, cleaning, and storage, ensures these tools remain effective and safe to use over time. Adhering to safety precautions, such as wearing protective gear, securing workpieces, controlling speed, and using cooling agents, minimizes the risk of accidents and tool damage.

Whether you’re a professional tradesperson or a DIY enthusiast, choosing the right brazing hole saw model, maintaining it properly, and using it safely will ensure efficient, accurate, and long-lasting performance. With the right knowledge and tools, cutting precise holes in any material becomes a straightforward and successful task.