Diamond drill bits are essential tools in industries ranging from construction and mining to geology and manufacturing, valued for their ability to cut through hard materials like concrete, stone, metal, and composites with precision and efficiency. Their performance is largely determined by design, diamond quality, bond type, and application-specific features. Below is a detailed exploration of prominent models across various categories, organized by industry use and leading brands.

In construction, diamond drill bits are used for drilling holes in concrete, brick, masonry, and reinforced concrete. Key features include high diamond concentration, durable bonds, and cooling systems to prevent overheating.

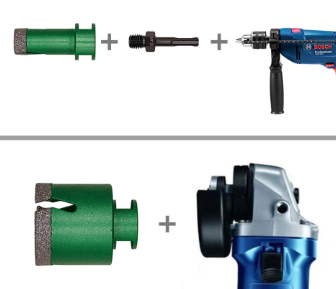

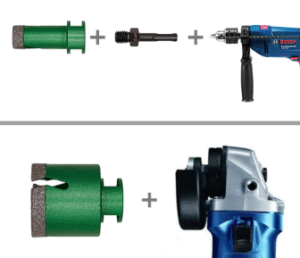

Bosch, a leader in power tool accessories, offers several models tailored for construction applications:

- Bosch Professional 2608595077 Diamond Core Bit: This core bit is designed for dry or wet drilling in concrete, brick, and stone. It features a segmented design with high-quality synthetic diamonds embedded in a nickel-alloy bond, ensuring fast material removal and long life. The bit has a 12mm diameter and a 300mm working length, making it suitable for medium-duty tasks like installing pipes or electrical conduits. Its hexagonal shank fits most standard drills, and the laser-welded segments enhance durability under high pressure.

- Bosch Professional 2608595109 Diamond Drill Bit Set: This set includes 6 bits (6mm, 8mm, 10mm, 12mm, 16mm, 20mm) for versatile use in concrete and masonry. Each bit uses a “Turbo” design with a spiral flute that improves debris removal and cooling, reducing friction and extending bit life. The diamonds are evenly distributed in a sintered bond, optimized for balanced cutting speed and wear resistance. The set comes with a storage case and is ideal for DIY enthusiasts and professionals alike, offering consistent performance across different hole sizes.

DeWalt’s Extreme series focuses on durability and speed for heavy-duty construction:

- DeWalt DW5470 Diamond Core Bit: A 4-inch diameter core bit designed for wet drilling in reinforced concrete. It features a “Perma-Shield” coating that resists corrosion and reduces heat buildup, while the high-density diamond matrix ensures aggressive cutting even through steel rebar. The bit has a 16-inch length and a 1-1/4 inch UNC thread, compatible with most core drill machines. Its optimized water channeling system ensures efficient cooling, making it suitable for continuous use on large construction sites.

- DeWalt DWA5472 Diamond Drill Bit: A 10mm diameter bit for dry drilling in concrete and masonry. It uses a “Speed 槽” design, with angled flutes that accelerate debris ejection, reducing clogging and improving drilling speed by up to 30% compared to standard bits. The diamond bond is tailored for medium-hard concrete, balancing cutting efficiency with longevity. The hex shank prevents slippage in drill chucks, and the bit is backed by DeWalt’s 3-year warranty.

Mining and geological exploration demand drill bits that can withstand extreme conditions, including hard rock formations, high pressure, and prolonged use. These bits prioritize wear resistance and penetration rate.

Sandvik is a global leader in mining equipment, with drill bits engineered for hard rock drilling:

- Sandvik DS4 Diamond Core Bit: A PQ-sized (85mm diameter) core bit designed for deep geological exploration. It uses a “Matrix II” bond, a proprietary metal matrix that combines tungsten carbide and synthetic diamonds for superior abrasion resistance in granite, gneiss, and quartzite. The bit features a “crown” design with strategically placed water holes to enhance cooling and flush out cuttings, preventing bit balling. Its threaded connection (API regular thread) ensures secure attachment to drill rods, and it is compatible with Sandvik’s DS series drill rigs, delivering consistent core recovery rates of over 95% in hard formations.

- Sandvik RH600 Diamond Drill Bit: A 115mm diameter bit for surface mining, optimized for drilling in iron ore and basalt. It uses large, high-quality synthetic diamonds (20-30 mesh) embedded in a tough cobalt-alloy bond, designed to maintain sharpness even in abrasive conditions. The bit’s “step-cut” profile reduces vibration, improving drilling stability and extending bit life by up to 40% compared to conventional designs. It integrates with Sandvik’s AutoMine system for automated drilling, enhancing safety and productivity in remote mining sites.

Atlas Copco specializes in mining and construction equipment, with drill bits known for reliability:

- Atlas Copco QL35 Diamond Core Bit: A 35mm diameter core bit for mineral exploration in soft to medium-hard rock. It features a “quick-lock” connection system that reduces setup time by 50%, allowing for fast bit changes during drilling operations. The diamond bond is adjustable based on rock type—softer bonds for abrasive rocks and harder bonds for dense formations. The bit’s slim design minimizes core loss, ensuring accurate geological sampling, and it is compatible with Atlas Copco’s Boomer and Simba drill rigs.

- Atlas Copco CC800 Diamond Drill Bit: An 80mm diameter bit for coal mining, designed to drill through coal seams and interbedded rock layers. It uses a hybrid bond combining resin and metal, providing flexibility to absorb impact while maintaining cutting efficiency. The bit’s carbide-reinforced shoulders protect against wear in abrasive coal, and its large flutes facilitate efficient removal of coal dust, reducing the risk of clogging. It is widely used in underground coal mines for blast hole drilling, with a service life of up to 500 meters in typical coal formations.

Oil and gas drilling requires diamond bits capable of operating at extreme depths (up to 10,000 meters) and high temperatures (over 200°C). Polycrystalline Diamond Compact (PDC) bits dominate this sector due to their hardness and resistance to wear.

Halliburton is a key player in oilfield services, offering advanced PDC bits:

- Halliburton Force 3D PDC Bit: A 12-1/4 inch PDC bit designed for horizontal and directional drilling in shale formations. It features 3D-shaped cutters with a “thermo-stable” diamond layer, engineered to withstand high temperatures in deep wells. The cutter placement is optimized using computational fluid dynamics (CFD) to reduce drag and improve hydraulics, enhancing penetration rates by up to 25% in tight shale. The bit’s steel body is reinforced with carbide inserts to resist erosion from drilling fluids, and it integrates with Halliburton’s DrillQuest software for real-time performance monitoring.

- Halliburton NovaX PDC Bit: A 8-1/2 inch bit for deep vertical wells in sandstone and limestone. It uses “Matrix Shield” technology, a tough metal matrix body that protects against impact and corrosion in high-pressure environments. The PDC cutters are arranged in a staggered pattern to distribute load evenly, reducing cutter wear and extending bit life to over 1,000 meters in typical formations. The bit’s enhanced fluid channels prevent balling in clay-rich zones, ensuring consistent performance in challenging oil and gas reservoirs.

Schlumberger’s PDC bits are known for innovation in extreme drilling conditions:

- Schlumberger PowerDrive Orbit PDC Bit: A 16-inch PDC bit for offshore drilling, designed for use in high-pressure, high-temperature (HPHT) reservoirs. It features “Adaptive Cutter Technology,” where cutters automatically adjust their angle based on rock hardness, optimizing cutting efficiency in heterogeneous formations. The bit’s body is made from a lightweight, high-strength alloy that reduces vibration, improving drilling stability in deepwater environments. It is compatible with Schlumberger’s M-I SWACO drilling fluid systems, ensuring effective cooling and debris removal.

- Schlumberger GeoTech PDC Bit: A 9-7/8 inch bit for unconventional gas drilling in the Marcellus and Permian basins. It uses ultra-hard PDC cutters with a diamond grit size of 10-15 microns, providing superior wear resistance in abrasive sandstone. The bit’s “FlowPro” hydraulics system maximizes fluid velocity at the cutter face, flushing away cuttings and reducing heat buildup. Field tests show a 30% increase in rate of penetration (ROP) compared to conventional bits, making it a preferred choice for cost-sensitive shale gas operations.

For cutting and shaping stone, gemstones, and glass, precision and minimal material damage are critical. These bits have fine diamond grits and specialized designs.

Alpha Tools focuses on lapidary and stoneworking tools:

- Alpha Tools 3mm Diamond Core Drill Bit: A small-diameter core bit for drilling gemstones like quartz and amethyst. It uses 60/80 mesh synthetic diamonds embedded in a nickel bond, providing a smooth, precise cut without chipping the stone. The bit has a 50mm length and a 3mm shank, compatible with hobbyist lapidary drills. Its hollow design allows for water cooling, essential for preventing heat damage to delicate gemstones. It is ideal for creating holes in beads or pendants, with a service life of up to 500 holes in medium-hard gemstones.

- Alpha Tools 20mm Diamond Router Bit: A router bit for shaping edges of marble and granite countertops. It features a rounded tip with 40/60 mesh diamonds in a sintered bond, designed to produce a polished finish in a single pass. The bit has a 1/4 inch shank and a 70mm length, suitable for use with handheld routers. Its “anti-chip” design minimizes edge damage, and the diamond distribution is optimized for consistent material removal, reducing the need for post-processing. It is widely used by stone fabricators for custom countertop designs.

Norton offers a range of abrasives, including stone-specific diamond bits:

- Norton Quantum 10mm Diamond Drill Bit: A versatile bit for drilling glass, ceramic, and porcelain. It uses ultra-fine 120/140 mesh diamonds in a resin bond, ensuring a clean, chip-free hole in brittle materials. The bit’s tip is rounded to reduce stress concentration, preventing glass from cracking during drilling. It requires constant water cooling, and its 100mm length allows for drilling through thick glass panels (up to 20mm thick). The shank is compatible with both electric drills and drill presses, making it suitable for DIY glass crafts and professional glass installation.

- Norton Clipper 50mm Diamond Saw Blade Drill Bit: A hybrid bit that combines drilling and cutting functions for large stone slabs. It has a circular blade with 30/40 mesh diamonds in a metal bond, designed to cut through granite and limestone while drilling a central hole for alignment. The bit has a 20mm shank and a 200mm length, used with heavy-duty stone drills. Its segmented design enhances cooling, and the diamond segments are laser-welded for durability, allowing it to cut through 100mm thick granite slabs with minimal vibration.

Diamond drill bits are also used in metalworking for drilling hard metals like tungsten carbide and composites, where traditional high-speed steel bits fail.

Dormer Pramet specializes in metalworking tools, including diamond bits for hard materials:

- Dormer Pramet CDX06 Diamond Drill Bit: A 6mm diameter bit for drilling tungsten carbide and hardened steel (up to 65 HRC). It uses polycrystalline diamond (PCD) tips brazed to a steel shank, providing hardness exceeding 8,000 HV for cutting through the hardest metals. The bit has a parabolic flute design that improves chip evacuation, reducing friction and extending tool life. It operates at speeds of 500-1,500 RPM with coolant, and is compatible with CNC machining centers for precision metalworking applications, such as aerospace component manufacturing.

- Dormer Pramet CDX12 Diamond Drill Bit: A 12mm diameter bit for drilling fiber-reinforced polymers (FRP) and carbon fiber composites. It features a PCD tip with a sharp, pointed geometry to prevent delamination of composite layers. The bit’s “chip breaker” flutes break up long composite chips, preventing clogging and ensuring a smooth hole finish. It is used in automotive and aerospace industries for drilling holes in composite panels, with a service life up to 10 times longer than carbide bits in FRP materials.

Kennametal is a leader in metalworking solutions, offering diamond bits for extreme applications:

- Kennametal KCD Diamond Core Bit: A 20mm diameter core bit for drilling through armor plate and ballistic steel. It uses a thick PCD layer (0.5mm) on a carbide substrate, designed to withstand the high impact forces of drilling hard metals. The bit’s cylindrical core design reduces material removal, lowering power consumption while maintaining precision. It is used in defense manufacturing for creating holes in armored vehicles, with a drilling speed of 10-15mm per minute in 50mm thick armor steel.

- Kennametal KCU Diamond Drill Bit: A 8mm diameter bit for drilling ceramic matrix composites (CMCs) used in gas turbine engines. It features a ultra-fine PCD grit (1-3 microns) for a mirror-finish hole, essential for maintaining the structural integrity of CMC components. The bit’s coolant channels deliver high-pressure coolant directly to the cutting zone, preventing thermal damage to the composite material. It operates at low speeds (300-500 RPM) to minimize heat generation, ensuring consistent performance in aerospace CMC machining.

Beyond mainstream applications, specialized diamond drill bits serve unique industries like dentistry, electronics, and art restoration.

Brasseler USA provides precision tools for dentistry, including diamond bits for tooth preparation:

- Brasseler 835-016 Diamond Bur: A 1.6mm diameter diamond bur for cavity preparation in teeth. It uses 150/180 mesh diamonds in a nickel-chrome bond, designed to remove tooth enamel with minimal vibration and patient discomfort. The bur has a tapered shape for precise cavity shaping, and its small size allows access to tight spaces in molars. It is compatible with dental handpieces operating at 300,000 RPM, and the sterile, single-use design ensures infection control.

- Brasseler 701-020 Diamond Polishing Bur: A 2.0mm diameter bur for polishing composite fillings. It uses ultra-fine 200/230 mesh diamonds in a flexible resin bond, producing a smooth, glossy finish on dental composites. The bur’s rounded tip prevents damage to surrounding tooth structure, and its slow wear rate ensures consistent polishing performance throughout the procedure. It is a staple in cosmetic dentistry for achieving natural-looking fillings.

SycoTec specializes in precision tools for electronics manufacturing:

- SycoTec 0.5mm Diamond Drill Bit: A micro-drill bit for drilling holes in printed circuit boards (PCBs) and semiconductor wafers. It uses synthetic diamonds embedded in a nickel bond, with a tip radius of less than 0.1mm for ultra-precise holes. The bit has a 3mm shank and a 20mm length, compatible with high-speed precision drills operating at 50,000-100,000 RPM. Its rigid design minimizes deflection, ensuring hole positional accuracy within ±0.01mm, critical for PCB interconnects.

- SycoTec 2mm Diamond Core Bit: A core bit for drilling glass substrates in LCD and OLED display manufacturing. It features a hollow design with 100/120 mesh diamonds, allowing for clean, burr-free holes in thin glass (0.3-1mm thick). The bit’s slow feed rate (0.1mm/s) and constant water cooling prevent glass breakage, and its compatibility with automated drilling systems ensures high-volume production efficiency in electronics factories.

Diamond drill bits are diverse tools, with models engineered for specific materials, industries, and operating conditions. From construction-grade core bits to micro-drills for electronics, each model combines diamond quality, bond type, and design features to deliver optimal performance. Brands like Bosch, Sandvik, Halliburton, and Brasseler lead in innovation, continuously refining diamond bit technology to meet the evolving demands of hard material drilling. Whether for heavy-duty mining or delicate dental work, the right diamond drill bit model ensures precision, efficiency, and longevity in every application.