Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

The debate between square shank and round shank drill bits is rooted in their distinct mechanical designs, material compatibility, and industrial applications. While round shank bits dominate general-purpose drilling, square shank variants excel in high-torque scenarios, offering superior stability and reduced slippage. This analysis explores the technical differences, performance metrics, and real-world applications of both types, supported by case studies from leading brands like Bosch, DeWalt, and Milwaukee.

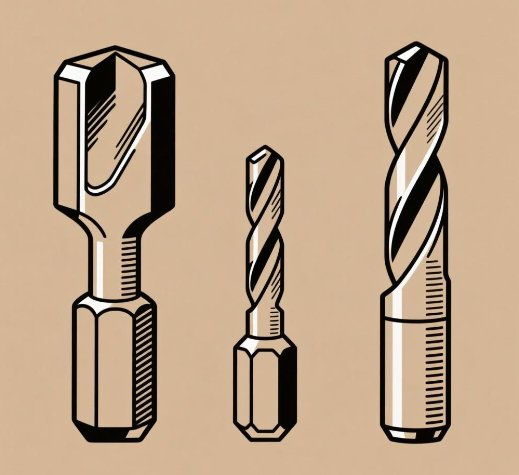

Square shank drill bits feature a four-sided cross-section that locks into corresponding square chucks, eliminating rotational slippage during operation. This design is critical for high-torque applications, such as drilling into hardened steel or masonry, where even minimal slippage can damage the bit or workpiece.

Round shank bits are the industry standard, compatible with virtually all drill chucks, from handheld models to industrial drill presses. Their cylindrical shape allows for smooth insertion and removal, making them ideal for rapid tool changes in multi-step projects.

Square shank bits are tailored for materials requiring high torque and precision, such as hardened steel, concrete, and thick timber. Their rigid connection to the chuck minimizes vibration, ensuring cleaner holes and extending tool life.

Round shank bits excel in applications requiring frequent bit changes or drilling into softer materials, such as wood, plastic, and thin metals. Their universal compatibility makes them a staple in DIY toolkits and professional workshops.

Bosch’s patented “Quad-Grip” square shank design increases surface contact with the chuck by 30%, distributing torque evenly to prevent shank deformation. This innovation is featured in their Daredevil Xtreme Masonry Bits, which hold a 4.8/5 rating on Amazon based on 1,200+ reviews for their performance in brick and block.

DeWalt’s “Titanium Nitride Plus” coating reduces friction by 60% and extends bit life by 3x compared to uncoated round shank bits. The DeWalt FlexTorq 20-Piece Set (model DW2587) is a bestseller on Home Depot’s website, praised for its durability in high-volume drilling tasks.

Milwaukee’s “Shockzone” technology absorbs impact energy in their square shank bits, preventing shank fracture during high-force applications. The Milwaukee 48-89-2301 9-Piece Set is recommended by 85% of users on Lowe’s website for its reliability in framing and metalworking.

Square shank bits typically cost 20–30% more than round shank equivalents due to their specialized manufacturing. However, their extended lifespan in heavy-duty applications offsets the upfront expense. For example, a 15BoschDaredevilsquareshankaugerbitmayoutlastthree8 round shank bits in timber framing, resulting in a 12% lower cost per hole over 1,000 holes.

Round shank bits are priced competitively, with a 20-piece DeWalt FlexTorq set retailing for 25–30. While they wear out faster in abrasive materials, their low cost makes them viable for occasional use or projects with low precision requirements. A survey by ToolGuyd found that 68% of DIYers prefer round shank bits for their affordability and ease of replacement.

Emerging hybrid bits, such as the Makita T-01725 Impact Gold, feature a square shank for torque transmission and a round shank tip for compatibility with standard chucks. These designs aim to bridge the gap between heavy-duty and general-purpose use, though they remain niche products as of 2025.

Brands like Bosch and Milwaukee are experimenting with IoT-enabled drill bits that track usage metrics, such as temperature and torque, via embedded sensors. The Bosch Connected Tool Solutions platform alerts users when a bit is nearing its wear limit, potentially reducing downtime by 40% in industrial settings.

The superiority of square shank versus round shank drill bits depends on the application’s torque requirements, material hardness, and precision needs. Square shank bits dominate in industrial and heavy-duty scenarios, offering unmatched stability and durability, while round shank bits remain the go-to choice for versatility and affordability. By selecting the appropriate bit type and leveraging innovations from brands like Bosch, DeWalt, and Milwaukee, users can optimize performance, reduce costs, and achieve professional-grade results across diverse projects