Square Shank vs. Round Shank Drill Bits

The debate between square shank and round shank drill bits is a longstanding one in the industrial and DIY communities. Both designs offer distinct advantages and limitations, making them suitable for specific applications. This article delves into the technical specifications, material compositions, and real-world performance of both types, while highlighting leading brands and models that exemplify their strengths. By analyzing their geometry, torque transmission, stability, and compatibility with power tools, we aim to provide a definitive guide for professionals and hobbyists alike.

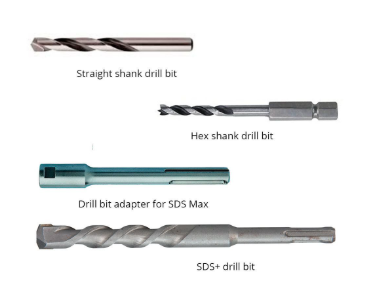

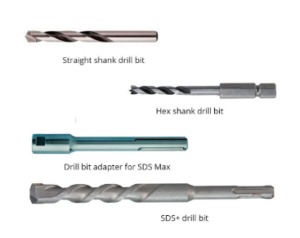

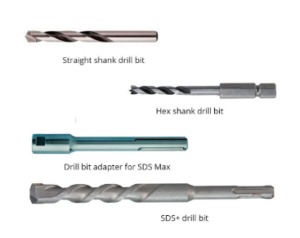

1. Understanding Shank Geometry: The Core Difference Between Square and Round Shank Drill Bits

The shank of a drill bit is the portion that fits into the chuck of a drill or drill press. Its design directly impacts torque transmission, bit stability, and compatibility with different tools.

1.1 Square Shank Drill Bits: Engineering for High Torque and Anti-Slip Performance

Square shank drill bits feature a four-sided, prismatic design that locks securely into compatible chucks, such as those found in impact drivers, drill presses, and specialized square-drive systems. This geometry ensures minimal slippage under high torque, making it ideal for heavy-duty applications like metal fabrication, automotive repair, and construction.

Key Advantages:

- Superior Torque Transmission: The flat sides of the square shank distribute force evenly, reducing the risk of bit rotation or ejection during operation.

- Enhanced Stability: The secure fit minimizes vibration, resulting in cleaner holes and extended tool life.

- Compatibility with Specialized Chucks: Many square shank bits are designed for use with quick-release or keyless chucks that prioritize precision and ease of use.

Limitations:

- Limited Tool Compatibility: Not all drills accept square shank bits, requiring users to invest in compatible equipment.

- Higher Cost: Specialized square shank bits, especially those with advanced coatings or materials, tend to be more expensive than their round shank counterparts.

1.2 Round Shank Drill Bits: Versatility and Universal Compatibility

Round shank drill bits are the most common type, featuring a cylindrical shank that fits into standard three-jaw chucks found in most handheld drills and drill presses. Their simplicity and widespread availability make them a go-to choice for general-purpose drilling tasks.

Key Advantages:

- Universal Compatibility: Round shank bits work with virtually any drill or drill press, eliminating the need for specialized equipment.

- Cost-Effectiveness: Due to their mass production and widespread use, round shank bits are often more affordable than square shank alternatives.

- Ease of Use: The cylindrical design allows for quick bit changes and straightforward operation, making them ideal for beginners and casual users.

Limitations:

- Potential for Slippage: Under high torque or heavy loads, round shank bits may rotate or slip within the chuck, leading to reduced precision and potential safety hazards.

- Limited Torque Capacity: While suitable for most light to medium-duty tasks, round shank bits may struggle with extremely hard materials or high-torque applications.

2. Material Composition and Coatings: How Shank Design Influences Durability and Performance

The material composition and coatings of a drill bit play a crucial role in its performance, heat resistance, and lifespan. Both square and round shank bits are available in a variety of materials, each tailored to specific applications.

2.1 High-Speed Steel (HSS): The Workhorse of Drill Bits

High-speed steel (HSS) is a popular choice for both square and round shank drill bits due to its balance of hardness, toughness, and heat resistance. HSS bits are suitable for drilling wood, plastic, and soft to medium-hard metals like aluminum and brass.

Leading Brands and Models:

- Bosch HSS-G Round Shank Drill Bits: Known for their precision-ground flutes and split points, these bits reduce walking and improve hole quality in metal.

- DEWALT Titanium-Coated HSS Square Shank Drill Bits: The titanium coating enhances wear resistance, while the square shank ensures secure fit in impact drivers for high-torque applications.

2.2 Cobalt Alloy: For Drilling Hardened Metals

Cobalt alloy drill bits, typically containing 5–8% cobalt, offer superior heat resistance and hardness compared to standard HSS. They are ideal for drilling stainless steel, cast iron, and other tough materials.

Leading Brands and Models:

- Irwin Industrial Tools Cobalt Round Shank Drill Bits: These bits feature a heavy-duty spiral flute design for efficient chip removal and reduced heat buildup.

- Makita Cobalt Square Shank Drill Bits: Designed for use with impact drivers, these bits combine cobalt’s durability with the anti-slip benefits of a square shank.

2.3 Carbide-Tipped: The Ultimate in Masonry and Concrete Drilling

Carbide-tipped drill bits are engineered for drilling into hard materials like concrete, brick, and stone. The carbide tip resists wear and maintains sharpness, while the shank design (often round or SDS) ensures compatibility with hammer drills.

Leading Brands and Models:

- Hilti Carbide-Tipped Round Shank Masonry Bits: These bits feature a reinforced core for added strength and a precision-ground carbide tip for clean holes in masonry.

- Bosch SDS-Plus Carbide-Tipped Square Shank Adapters: While SDS bits are typically round, some models come with square shank adapters for use with standard chucks, combining the benefits of both designs.

3. Application-Specific Performance: Where Square and Round Shank Bits Excel

The choice between square and round shank drill bits ultimately depends on the application. Below, we explore scenarios where each design shines.

3.1 Square Shank Drill Bits: Ideal for High-Torque and Heavy-Duty Applications

Square shank drill bits are the preferred choice for tasks that demand maximum torque and stability. Their secure fit in compatible chucks ensures minimal slippage, making them indispensable in the following scenarios:

Metal Fabrication and Automotive Repair:

- Drilling holes in thick steel plates, automotive frames, or engine components requires a bit that can withstand high torque without slipping. Square shank bits, especially those made from cobalt or carbide, excel in these applications.

- Example Model: DEWALT DW1152 1/2-Inch Square Shank Cobalt Drill Bit – Designed for drilling into hardened steel, this bit features a split point tip for reduced walking and a square shank for secure fit in impact drivers.

Construction and Masonry:

- While most masonry bits feature round shanks (or SDS designs), some high-end models offer square shank adapters for use with standard drills. These are useful when a hammer drill is unavailable, and the user needs to drill into concrete or brick.

- Example Model: Bosch DAREDEVIL Square Shank Carbide-Tipped Masonry Bit – This bit combines a carbide tip for durability with a square shank adapter for compatibility with standard chucks.

Woodworking and Cabinet Making:

- For tasks that require precise, high-torque drilling, such as creating mortises or dowel holes, square shank bits offer superior stability compared to round shank alternatives.

- Example Model: Freud Tools Square Shank Forstner Bit – Designed for clean, flat-bottomed holes in wood, this bit features a square shank for reduced vibration and improved accuracy.

3.2 Round Shank Drill Bits: The Versatile Choice for General-Purpose Drilling

Round shank drill bits are the go-to option for everyday drilling tasks due to their universal compatibility and ease of use. They are suitable for a wide range of materials and applications, including:

DIY Projects and Home Repairs:

- From hanging shelves to assembling furniture, round shank bits are perfect for light to medium-duty tasks that don’t require extreme torque or precision.

- Example Model: Craftsman 20-Piece Round Shank HSS Drill Bit Set – This comprehensive set includes bits for wood, metal, and plastic, making it ideal for general-purpose use.

Electrical and Plumbing Work:

- Drilling holes for wires, pipes, or conduits in wood or drywall is a common task in electrical and plumbing installations. Round shank bits, especially those with spade or auger designs, are well-suited for these applications.

- Example Model: IRWIN Tools Speedbor Max Speed Round Shank Auger Bit – Featuring a screw-tip design for self-feeding action, this bit is ideal for drilling deep holes in wood for plumbing or electrical work.

Light Metal Drilling:

- While round shank bits may not be the best choice for hardened steel, they perform admirably when drilling soft metals like aluminum, copper, or brass. HSS or cobalt-coated round shank bits are suitable for these tasks.

- Example Model: Milwaukee Electric Tool 15-Piece Round Shank Cobalt Drill Bit Set – Designed for drilling into metal, this set includes bits in various sizes for versatility.

4. Brand Spotlight: Leading Manufacturers of Square and Round Shank Drill Bits

Several brands have established themselves as industry leaders in the production of high-quality drill bits. Below, we highlight some of the most reputable manufacturers and their flagship models.

4.1 DEWALT: Innovation and Durability in Square Shank Drill Bits

DEWALT is renowned for its robust, high-performance tools, and its drill bits are no exception. The brand offers a wide range of square shank bits designed for impact drivers and other high-torque applications.

Flagship Model: DEWALT DW1169 9-Piece Black Oxide Coated Square Shank Drill Bit Set

- Features: Black oxide coating for rust resistance, 135-degree split point for reduced walking, and a square shank for secure fit in impact drivers.

- Applications: Ideal for drilling into metal, wood, and plastic in automotive, construction, and metal fabrication settings.

4.2 Bosch: Precision and Versatility in Round Shank Drill Bits

Bosch is a trusted name in the power tool industry, and its drill bits are known for their precision and durability. The brand offers a comprehensive range of round shank bits for various materials and applications.

Flagship Model: Bosch Daredevil 15-Piece Round Shank Spade Bit Set

- Features: Full-cone threaded tips for fast, effortless drilling, paddle-style design for clean holes, and a rounded shank for compatibility with standard chucks.

- Applications: Perfect for drilling large-diameter holes in wood for electrical, plumbing, or HVAC installations.

4.3 Makita: High-Performance Cobalt and Carbide-Tipped Bits

Makita is synonymous with quality and innovation, and its drill bits are no exception. The brand offers a range of cobalt and carbide-tipped bits, including both square and round shank designs.

Flagship Model: Makita B-49373 5-Piece Carbide-Tipped Round Shank Masonry Bit Set

- Features: Carbide tip for durability, reinforced core for added strength, and a round shank for compatibility with hammer drills or standard chucks (with adapters).

- Applications: Designed for drilling into concrete, brick, and stone in construction and renovation projects.

4.4 IRWIN Tools: Specialized Bits for Every Task

IRWIN Tools is known for its specialized drill bits that cater to specific applications. From auger bits for wood to cobalt bits for metal, the brand offers a comprehensive range of both square and round shank designs.

Flagship Model: IRWIN Tools 3018002 29-Piece Round Shank High-Speed Steel Drill Bit Set

- Features: Cobalt-coated bits for extended life, 135-degree split points for reduced walking, and a variety of sizes for versatility.

- Applications: Suitable for drilling into metal, wood, and plastic in general-purpose and light-duty applications.

5. Future Trends: Innovations in Shank Design and Material Technology

The drill bit industry is constantly evolving, with manufacturers introducing new materials, coatings, and designs to improve performance and durability. Some emerging trends include:

5.1 Advanced Coatings for Enhanced Wear Resistance

Brands are increasingly using advanced coatings like titanium nitride (TiN), titanium aluminum nitride (TiAlN), and diamond-like carbon (DLC) to extend the lifespan of drill bits. These coatings reduce friction, resist heat buildup, and protect against wear and corrosion.

5.2 Modular Shank Designs for Versatility

Some manufacturers are experimenting with modular shank designs that allow users to switch between square and round shanks depending on the application. This versatility could make drill bits more adaptable to different tools and tasks.

5.3 Smart Drill Bits with Integrated Sensors

The rise of Industry 4.0 has led to the development of smart tools, and drill bits are no exception. Some prototypes feature integrated sensors that monitor temperature, torque, and vibration, providing real-time feedback to users to optimize performance and prevent tool failure.

6. Conclusion: Choosing the Right Shank Design for Your Needs

The choice between square and round shank drill bits ultimately depends on the specific requirements of your project. Square shank bits excel in high-torque, heavy-duty applications where stability and anti-slip performance are critical. Round shank bits, on the other hand, offer universal compatibility and versatility, making them ideal for general-purpose drilling tasks.

When selecting a drill bit, consider the following factors:

- Material to be drilled: Choose a bit material (HSS, cobalt, carbide) that matches the hardness of the workpiece.

- Torque requirements: For high-torque applications, opt for a square shank bit designed for impact drivers or drill presses.

- Tool compatibility: Ensure your drill or drill press can accommodate the shank design of your chosen bit.

- Budget: While high-end bits offer superior performance, there are affordable options available for casual users and DIY enthusiasts.

By understanding the strengths and limitations of both square and round shank drill bits, you can make an informed decision that ensures precision, efficiency, and longevity in your drilling tasks. Whether you’re a professional tradesperson or a hobbyist, investing in the right drill bit is a small but crucial step toward achieving professional-quality results.