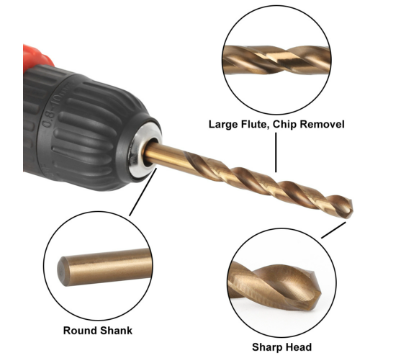

Fully ground straight shank twist drill bits are essential tools in metalworking, woodworking, and general fabrication, valued for their precision, durability, and consistent performance. Unlike rolled drill bits, which are formed by rolling metal into shape, fully ground bits undergo a grinding process that refines their cutting edges, flutes, and shanks to exact tolerances. This results in sharper cutting angles, smoother flutes for efficient chip evacuation, and tighter dimensional accuracy—critical for applications requiring precise hole diameters and clean finishes. Below is a comprehensive overview of prominent models from leading brands, detailing their specifications, materials, coatings, and ideal use cases.

Bosch, a globally recognized leader in power tools and accessories, offers a range of fully ground straight shank twist drill bits under its Professional line, designed for professional tradespeople and industrial users. These bits are engineered for high performance across various materials, from mild steel to non-ferrous metals and plastics.

The Bosch 2608585249 is a popular set of fully ground twist drill bits crafted from high-speed steel (HSS-G), a material known for its excellent heat resistance and wear resistance, making it suitable for drilling in mild steel, cast iron, copper, aluminum, and plastics. The set includes 19 bits with diameters ranging from 1.0 mm to 10.0 mm, covering the most commonly used sizes in general metalworking. Each bit features a fully ground flute design with a 118° point angle, optimized for balanced cutting forces and efficient chip removal. The straight shank conforms to DIN 338 standards, ensuring compatibility with most drill chucks and drill presses. A key feature of these bits is their precision grinding, which ensures consistent hole diameters and reduces the risk of wandering during initial contact with the workpiece. The surface of each bit is untreated (bright finish), allowing for easy inspection of wear and ensuring smooth chip flow. This model is ideal for maintenance, repair, and production environments where versatility and reliability are paramount.

For more demanding applications involving stainless steel, heat-resistant alloys, and hard metals, Bosch offers the 2608585312 model, constructed from HSS-Co (high-speed steel with cobalt). Cobalt content (typically 5-8%) enhances the material’s hot hardness, allowing the bit to maintain its cutting edge at higher temperatures generated during drilling in hard materials. This fully ground bit features a 130° split point tip, which self-centers quickly to prevent slipping and reduces axial pressure, making it easier to start holes in smooth or hard surfaces. The flutes are fully ground with a parabolic design, which improves chip evacuation—critical when drilling deep holes, as it prevents chip clogging that can cause overheating and bit damage. Available in diameters from 3.0 mm to 12.0 mm, the 2608585312 has a straight shank compatible with standard chucks and is coated with a titanium nitride (TiN) layer. The TiN coating, characterized by its gold color, reduces friction between the bit and workpiece, minimizes heat buildup, and extends tool life. This model is a favorite among automotive mechanics, aerospace technicians, and metal fabricators working with tough materials.

DeWalt, a brand synonymous with rugged durability and professional-grade tools, produces fully ground straight shank twist drill bits designed to withstand heavy-duty use in construction, manufacturing, and metalworking. Their bits focus on precision, longevity, and ease of use, with features tailored to reduce user fatigue and improve productivity.

The DeWalt DW1354 is a comprehensive set of 29 fully ground twist drill bits, crafted from high-quality HSS-G steel, making it suitable for drilling in mild steel, iron, brass, aluminum, and wood. The set includes diameters from 1/16 inch (1.5875 mm) to 1/2 inch (12.7 mm), covering a wide range of hole sizes for versatile applications. Each bit undergoes a fully ground manufacturing process that refines the 118° point angle, ensuring sharp, consistent cutting edges that penetrate materials quickly with minimal effort. The flutes are spiral-shaped and fully ground to optimize chip removal, preventing debris buildup and reducing the risk of bit jamming. The straight shank is precision-ground to DIN 338 specifications, ensuring a secure grip in drill chucks and reducing slippage during high-torque drilling. The bits feature a bright finish, which allows users to monitor wear patterns easily, ensuring timely replacement before performance degrades. The DW1354 set is packaged in a durable case with labeled compartments for organized storage, making it a practical choice for workshops, job sites, and DIY enthusiasts seeking professional results.

For drilling in stainless steel, cast iron, and other high-strength alloys, the DeWalt DW1369 is a standout model, constructed from HSS-Co steel with 8% cobalt content. This high cobalt concentration enhances the bit’s hardness and heat resistance, enabling it to maintain cutting efficiency even when drilling at high speeds or in materials that generate significant friction. The DW1369 features a fully ground 135° split point tip, which self-centers instantly, eliminating the need for a pilot hole and reducing the chance of wandering—especially useful when working with slippery or hard surfaces like stainless steel. The flutes are fully ground with a variable helix design, where the spiral angle increases from the tip to the shank. This design promotes faster chip evacuation, as the steeper helix near the tip captures chips quickly, while the shallower helix near the shank moves them away from the cutting zone efficiently. Available in diameters from 3.2 mm to 10 mm, the DW1369 has a straight shank and is coated with titanium aluminum nitride (TiAlN), a multi-layer coating that offers superior wear resistance compared to TiN. The TiAlN coating also reduces friction and heat, extending the bit’s lifespan in high-temperature applications. This model is ideal for professional metalworkers, plumbers, and HVAC technicians who regularly work with tough materials.

Makita, a Japanese brand renowned for precision engineering, offers fully ground straight shank twist drill bits that combine accuracy with long-term durability. Their bits are designed for both professional and industrial use, with a focus on tight tolerances and consistent performance across diverse materials.

The Makita D-46273 is a 10-piece set of fully ground twist drill bits made from HSS-G steel, suitable for drilling in mild steel, copper, brass, aluminum, and plastics. The set includes diameters from 2.0 mm to 10.0 mm, incrementing by 1.0 mm, making it a versatile choice for general-purpose drilling tasks. Each bit features a fully ground 118° point angle, which balances cutting aggressiveness with precision, ensuring clean holes in both soft and medium-hard materials. The flutes are spiral-shaped and fully ground to a smooth finish, which reduces friction between the bit and chips, allowing for efficient evacuation and preventing overheating. The straight shank is precision-ground to ensure a secure fit in standard drill chucks, minimizing runout and ensuring accurate hole placement. A notable feature of the D-46273 is its strict dimensional control—each bit’s diameter is held to tight tolerances (±0.01 mm), making it suitable for applications where hole size accuracy is critical, such as in electrical panel installation or precision machining. The bits have a bright, uncoated finish, which allows for easy inspection of cutting edges and ensures compatibility with cutting fluids, which can be applied to further reduce heat and extend tool life. This set is highly regarded by mechanics, machinists, and DIY users for its reliability and consistent performance.

For heavy-duty applications involving stainless steel, heat-treated alloys, and cast iron, Makita offers the D-75454 model, constructed from HSS-Co steel with 5% cobalt. This cobalt addition enhances the bit’s hardness and thermal stability, enabling it to withstand the high temperatures generated when drilling hard materials without losing its cutting edge. The D-75454 features a fully ground 130° split point tip, which is self-centering and reduces axial force, making it easier to start holes and improving accuracy. The flutes are fully ground with a deep, parabolic design that increases chip capacity, ensuring efficient removal of debris even during deep drilling operations. Available in diameters from 4.0 mm to 12.0 mm, the bit has a straight shank compatible with standard chucks and is coated with a titanium carbonitride (TiCN) layer. TiCN coating offers a balance of hardness and lubricity, reducing friction and wear while providing excellent adhesion to the HSS-Co substrate, ensuring long-lasting performance. The D-75454 is also designed with a reinforced shank, which reduces the risk of breakage under high torque, a common issue when drilling hard materials. This model is widely used in aerospace, automotive, and industrial manufacturing where drilling precision and tool longevity are critical.

Irwin Tools, a heritage brand with over a century of experience, produces fully ground straight shank twist drill bits known for their innovation and performance. Their offerings cater to both professional and consumer markets, with models designed for specific materials and applications.

The Irwin 3018002 is an industrial-grade set of 29 fully ground twist drill bits, crafted from premium HSS-G steel, making it suitable for drilling in mild steel, cast iron, aluminum, brass, and wood. The set includes diameters from 1/16 inch (1.5875 mm) to 1/2 inch (12.7 mm), with fractional, metric, and wire gauge sizes to cover a wide range of drilling needs. Each bit features a fully ground 118° point angle, which is optimized for general-purpose drilling, providing a balance of speed and precision. The flutes are fully ground with a spiral design that promotes efficient chip evacuation, reducing the risk of clogging and overheating. A key innovation in the 3018002 is Irwin’s “Turbo” flute design, which features a variable helix angle that increases from the tip to the shank. This design allows for faster chip removal, as the steeper helix at the tip captures chips quickly, while the shallower helix near the shank moves them away from the cutting zone, improving overall drilling efficiency. The straight shank is precision-ground to ensure a secure fit in drill chucks, minimizing slippage and ensuring accurate hole placement. The bits have a bright finish, which is compatible with cutting fluids and allows for easy inspection of wear. This set is ideal for industrial workshops, construction sites, and professional tradespeople who require a versatile, reliable drill bit set for daily use.

For drilling in stainless steel, high-alloy steels, and other hard materials, the Irwin 3024006 is a top-tier model constructed from HSS-Co steel with 5% cobalt. This cobalt content significantly enhances the bit’s hot hardness, allowing it to maintain its cutting edge at elevated temperatures, which is crucial when drilling hard materials that generate high friction. The 3024006 features a fully ground 135° split point tip, which self-centers to prevent wandering and reduces the need for pilot holes, saving time and improving accuracy. The flutes are fully ground with a parabolic design that increases chip capacity, ensuring efficient debris removal even during deep drilling. Available in diameters from 3.0 mm to 10.0 mm, the bit has a straight shank and is coated with Irwin’s proprietary “Blue Groove” coating, a titanium-based coating that reduces friction, dissipates heat, and resists wear. The Blue Groove coating also acts as a lubricant, minimizing chip adhesion and extending tool life. Additionally, the 3024006 features a reinforced web, which increases the bit’s strength and reduces the risk of breakage under high torque. This model is a favorite among metal fabricators, mechanics, and engineers working with tough, high-strength materials.

Milwaukee Tool is known for producing heavy-duty tools designed for the most demanding job sites, and their fully ground straight shank twist drill bits are no exception. These bits are engineered for durability, speed, and precision in professional applications.

The Milwaukee 48-89-2330 is a 29-piece set of fully ground twist drill bits made from high-quality HSS-G steel, suitable for drilling in mild steel, iron, aluminum, brass, and plastics. The set includes diameters from 1/16 inch to 1/2 inch, with clear labeling for easy size identification. Each bit undergoes a rigorous fully ground manufacturing process that ensures sharp, consistent cutting edges and precise hole diameters. The 118° point angle is optimized for general-purpose drilling, providing fast penetration and clean cuts in a variety of materials. The flutes are fully ground with a spiral design that enhances chip evacuation, reducing heat buildup and preventing jamming. The straight shank is precision-ground to DIN 338 standards, ensuring a secure fit in all standard drill chucks, including keyless chucks, which are common in modern power drills. A unique feature of the 48-89-2330 is Milwaukee’s “Max-Life” coating, a proprietary treatment that increases wear resistance and reduces friction, extending the bit’s lifespan compared to uncoated bits. The coating also helps to dissipate heat, which is critical for maintaining performance during prolonged use. This set is packaged in a durable, impact-resistant case with a secure latch, making it easy to transport and store on job sites. It is highly recommended for construction workers, electricians, and maintenance professionals who need a reliable, long-lasting drill bit set for daily use.

For extreme applications involving stainless steel, heat-resistant alloys, and hardened steel, the Milwaukee 48-89-2630 is a premium model constructed from HSS-Co steel with 8% cobalt. This high cobalt content makes the bit exceptionally hard and heat-resistant, allowing it to drill through tough materials with minimal wear. The 48-89-2630 features a fully ground 135° split point tip, which self-centers instantly, eliminating the need for pilot holes and reducing the risk of slipping—even on smooth or angled surfaces. The flutes are fully ground with a deep, parabolic design that increases chip capacity, ensuring efficient removal of debris during deep drilling, which is essential for preventing overheating and bit damage. Available in diameters from 3.2 mm to 12.7 mm, the bit has a straight shank and is coated with Milwaukee’s “Titanium Enhanced” coating, which provides superior wear resistance and reduces friction, extending tool life in high-temperature applications. The coating also has a low coefficient of friction, which minimizes chip adhesion and makes the bit easier to clean after use. Additionally, the 48-89-2630 features a reinforced shank and web, which increases its strength and resistance to breakage under high torque, a common challenge when drilling hard materials. This model is trusted by professional metalworkers, fabricators, and engineers in industries such as aerospace, automotive, and heavy machinery manufacturing.

Kennametal, a global leader in metalworking solutions, specializes in high-performance cutting tools, including fully ground straight shank twist drill bits designed for precision machining and industrial applications. Their bits are engineered for extreme accuracy and long life in demanding environments.

While many brands focus on HSS and HSS-Co bits, Kennametal offers the KSEM series, a range of fully ground straight shank twist drill bits constructed from solid carbide, a material renowned for its hardness and wear resistance. Carbide bits are capable of drilling in materials that HSS bits cannot handle, such as hardened steel (up to 50 HRC), cast iron, and superalloys like Inconel. The KSEM series features a fully ground design with a 140° point angle, optimized for carbide’s properties, providing excellent penetration and chip control in hard materials. The flutes are fully ground with a spiral design that ensures efficient chip evacuation, which is critical for carbide bits, as they are more brittle than HSS and can break if chips clog the flutes. The straight shank is precision-ground to ensure compatibility with tool holders and drill chucks used in CNC machines and industrial drill presses. The KSEM bits are coated with Kennametal’s “KORLOY” TiAlN coating, which enhances wear resistance and reduces friction, extending tool life and allowing for higher cutting speeds. Available in diameters from 3.0 mm to 20.0 mm, these bits are designed for high-precision applications, such as mold making, die casting, and aerospace component manufacturing, where hole accuracy and surface finish are critical. The KSEM series is ideal for industrial settings where productivity and tool life are paramount, as carbide bits can operate at higher speeds than HSS, reducing cycle times.

For applications that require the versatility of HSS with enhanced performance, Kennametal’s KCD series offers fully ground straight shank twist drill bits made from HSS-Co steel with 10% cobalt, one of the highest cobalt contents available. This high cobalt concentration provides exceptional hot hardness, making the KCD series suitable for drilling in stainless steel, heat-resistant alloys, and other hard materials at high speeds. The bits feature a fully ground 135° split point tip, which self-centers to ensure accurate hole placement and reduces axial force, making them easier to use in both manual and automated drilling operations. The flutes are fully ground with a parabolic design that increases chip capacity, ensuring efficient debris removal even during deep drilling. The straight shank is precision-ground to tight tolerances, ensuring a secure fit in tool holders and reducing runout, which is critical for maintaining hole accuracy. The KCD series bits are coated with TiAlN, which provides superior wear resistance and heat dissipation, extending tool life in high-temperature applications. Available in diameters from 2.0 mm to 16.0 mm, these bits are widely used in automotive manufacturing, power generation, and heavy industry, where drilling performance and reliability are essential.

Sandvik Coromant, a pioneer in cutting tool technology, offers fully ground straight shank twist drill bits designed for precision, efficiency, and long life in industrial machining. Their bits are engineered using advanced materials and coatings to meet the demands of modern manufacturing.

The Sandvik Coromant R840 is a premium fully ground straight shank twist drill bit constructed from micrograin carbide, a material with extremely fine grain structure that provides superior hardness and toughness compared to conventional carbide. This makes the R840 ideal for drilling in hardened steel (up to 55 HRC), cast iron, and superalloys, where precision and tool life are critical. The R840 features a fully ground 140° point angle with a special edge preparation that reduces chipping and improves cutting stability, even in hard materials. The flutes are fully ground with a variable helix design, which optimizes chip evacuation by adjusting the spiral angle along the length of the bit, ensuring that chips are removed quickly and efficiently, preventing clogging and overheating. The straight shank is precision-ground to ISO standards, ensuring compatibility with a wide range of tool holders and drill chucks used in CNC machining centers and industrial drill presses. The R840 is coated with Sandvik Coromant’s “CVD TiCN-Al2O3-TiN” coating, a multi-layer coating that provides exceptional wear resistance, heat resistance, and oxidation resistance. This coating allows the bit to operate at high cutting speeds without losing performance, reducing cycle times and increasing productivity. Available in diameters from 3.0 mm to 25.0 mm, the R840 is a favorite among precision machinists, aerospace manufacturers, and mold makers who require the highest level of accuracy and tool reliability.

For applications that balance performance and cost, Sandvik Coromant’s HSS-E series offers fully ground straight shank twist drill bits made from HSS-Co steel with 8% cobalt. The HSS-E designation indicates a high-performance high-speed steel grade, optimized for drilling in stainless steel, heat-resistant alloys, and medium-hard steels. These bits feature a fully ground 135° split point tip, which self-centers to ensure accurate hole placement and reduces the need for pilot holes, improving efficiency. The flutes are fully ground with a spiral design that enhances chip evacuation, ensuring smooth drilling and reducing heat buildup. The straight shank is precision-ground to ensure a secure fit in drill chucks, minimizing runout and ensuring consistent hole diameters. The HSS-E series bits are coated with Sandvik Coromant’s “TiAlN” coating, which provides excellent wear resistance and reduces friction, extending tool life and allowing for higher cutting speeds. Available in diameters from 1.0 mm to 20.0 mm, these bits are widely used in general engineering, automotive manufacturing, and metal fabrication, where a balance of performance, durability, and cost-effectiveness is required.

Fully ground straight shank twist drill bits are indispensable tools in modern manufacturing, construction, and maintenance, offering precision, durability, and efficiency across a wide range of materials. Leading brands like Bosch, DeWalt, Makita, Irwin, Milwaukee, Kennametal, and Sandvik Coromant have developed specialized models tailored to specific applications, from general-purpose drilling in mild steel and wood to extreme tasks involving stainless steel, superalloys, and hardened metals. Key features such as HSS-G and HSS-Co materials, cobalt content, split point tips, optimized flute designs, and advanced coatings (TiN, TiAlN, TiCN) ensure that these bits deliver consistent performance, long life, and accurate results. Whether for professional tradespeople, industrial manufacturers, or DIY enthusiasts, choosing the right fully ground drill bit model—based on material compatibility, size requirements, and application demands—ensures efficient, high-quality drilling operations. As technology advances, these bits continue to evolve, with ongoing innovations in materials and manufacturing processes further enhancing their capabilities and expanding their range of applications.