Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

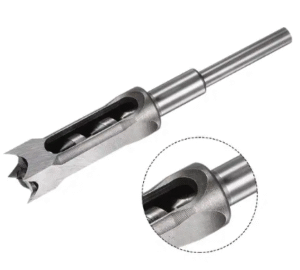

The Minimum Diameter of the Hollow Drill Bit: Specifications, Standards, and Brand Models

When discussing hollow drill bits, also referred to as core drill bits or annular cutters in many industrial applications, one of the most critical specifications that both professionals and enthusiasts consider is the minimum available diameter. The hollow drill bit is distinct from the traditional solid twist drill bit because it removes a cylindrical core of material, reducing the energy required for drilling while also leaving behind a clean hole with precise dimensions. Understanding the minimum diameter is essential, as it determines the smallest hole size that can be achieved with hollow drill technology, which is especially important in applications such as construction, metalworking, glass cutting, ceramic drilling, and plumbing installations. Generally, the minimum diameter of hollow drill bits ranges from about 6 mm to 12 mm depending on the material they are designed to cut, with some specialized precision hollow drill bits for glass and ceramics going as low as 5 mm. For heavy-duty applications such as structural steel or concrete coring, however, the smallest diameter tends to start at around 12 mm, since smaller diameters would compromise the structural integrity of the hollow tube design.

General Diameter Range of Hollow Drill Bits

The standard diameter range of hollow drill bits typically starts at the smallest available size for specific applications and expands to very large diameters for heavy drilling tasks. For example, in construction and concrete core drilling, diameters can range from 12 mm up to 500 mm or even more. For glass and ceramic hollow bits, the minimum diameter can be around 5 mm, making them suitable for delicate work such as installing bathroom fixtures or drilling tiles. For metal annular cutters, the minimum diameter usually starts at 12 mm or 14 mm because the design requires enough wall thickness for durability while cutting through tough steel. Therefore, the minimum diameter depends heavily on the category: in glass and ceramic cutting bits it can be as small as 5 mm, in metal annular cutters it is typically 12 mm, and in concrete hollow core bits it is generally no smaller than 12 mm to 18 mm.

Factors Determining the Minimum Diameter of Hollow Drill Bits

The minimum diameter of hollow drill bits is influenced by several engineering and material factors. First, the structural integrity of the cutting edge is vital. If the diameter is too small, the walls of the hollow bit will be too thin and prone to cracking or breaking under stress. Second, the material being drilled plays a role, since harder materials like concrete or structural steel demand thicker cutting edges and more durable tips such as tungsten carbide or diamond segments. Third, the intended application defines the range, as smaller diameters are more often used in tile, ceramic, and glass applications where holes for screws or pipes must be neat and precise. Finally, the type of shank and compatibility with power tools limit how small a hollow drill bit can be manufactured while still ensuring safety and effective torque transfer.

Minimum Diameter in Metalworking Annular Cutters

In the field of metalworking, hollow drill bits are commonly known as annular cutters, and these are widely used with magnetic drill presses. The minimum diameter of annular cutters typically starts at 12 mm or 14 mm, depending on the brand. For instance, Hougen Manufacturing, a globally recognized name in annular cutters, offers a minimum diameter of 12 mm (model HMD904 cutter set), which is designed for creating precise holes in structural steel. Similarly, Fein annular cutters, such as the Fein KBH 25 series, start at 14 mm diameter. Evolution Power Tools offers annular cutters that also begin at around 12 mm, with their Raptor series including 12 mm, 14 mm, and larger sizes. This standardization arises because cutting through metal demands enough rigidity in the cutter walls to withstand high torque and cutting pressure.

Minimum Diameter in Concrete and Masonry Core Bits

For concrete, brick, and stone, hollow drill bits are often called core drill bits or masonry core bits, and the minimum diameter tends to be larger than in glass or ceramics. For instance, Bosch offers the SDS-plus-9 CoreCutter drill bits that start at a minimum diameter of 14 mm, making them suitable for installing anchors or running cables through masonry. Hilti, another leading brand in construction tools, provides core drill bits with minimum diameters starting at 12 mm, such as the Hilti DD-BI diamond core bits, which are commonly used for drilling through reinforced concrete. Makita’s diamond core drill bits, like the Makita D-42200 series, also start at around 12 mm. This relatively larger minimum is necessary because when cutting through stone and concrete, the hollow bit must withstand immense friction and heat, which would quickly destroy a thinner-walled bit of smaller diameter.

Minimum Diameter in Glass and Ceramic Hollow Drill Bits

Glass and ceramic drilling requires more precision, and in this field, the minimum diameter of hollow drill bits can be significantly smaller compared to concrete or steel. Brands such as Bosch, Neiko, and DiamondSure produce diamond-tipped hollow bits designed specifically for tile, glass, and ceramics, with minimum diameters starting from 5 mm. For example, Bosch’s Glass and Tile Drill Bit Set includes diamond hollow bits as small as 5 mm, which are perfect for creating screw holes in bathroom tiles. DiamondSure hollow bits start at 6 mm, and these are often used in DIY projects for drilling into porcelain and glass without cracking the surface. Neiko’s diamond hole saw set provides 5 mm and 6 mm hollow drill bits, which are considered some of the smallest available in the consumer market. These smaller diameters are made possible because the drilling is performed at low speed with water cooling, reducing stress on the tool and material.

Examples of Brands and Models with Minimum Diameters

Bosch: Bosch offers multiple ranges of hollow drill bits. For metal annular cutters, Bosch’s Rotabroach series starts at 12 mm. For glass and ceramic, Bosch diamond hollow bits start at 5 mm, making them among the smallest available. For masonry and concrete, Bosch SDS core bits start at 14 mm.

Hilti: Hilti specializes in heavy-duty construction and concrete drilling. Their DD-BI diamond core bits start at 12 mm and are often used in professional construction for installing cables and pipes through reinforced concrete.

Makita: Makita produces a variety of diamond-tipped core bits for masonry that start at around 12 mm. Their tile and glass sets, however, include 6 mm and 8 mm options.

Hougen: Hougen is well-known for its annular cutters used in metalworking. The Hougen RotaLoc Plus cutters start at 12 mm diameter, designed for use with magnetic drills.

Evolution: Evolution Power Tools offers annular cutters starting at 12 mm, such as the Evolution Cyclone annular cutters.

Neiko: Neiko’s diamond hole saw set includes very small diameters, starting at 5 mm, making them a popular option for home use on glass and ceramic.

DiamondSure: DiamondSure hollow core bits for glass and tile also start at 6 mm, designed for precision drilling in fragile materials.

Fein: Fein annular cutters, especially in their KBH series, start at 14 mm, reflecting the company’s focus on metal drilling.

Applications of Minimum Diameter Hollow Drill Bits

The availability of small-diameter hollow drill bits expands their application across multiple industries. In construction, 12 mm hollow core bits are frequently used for installing conduits, anchors, and cable pathways. In plumbing, small hollow bits for tile and glass, starting at 5 mm, allow installers to make neat holes without cracking fragile surfaces. In electrical installations, hollow drill bits are used for creating pass-throughs in walls and tiles to run wires. In metal fabrication, annular cutters starting at 12 mm make it possible to drill bolt holes through thick steel plates with less effort compared to solid drill bits. In DIY and hobbyist projects, small hollow bits as small as 5 mm are commonly used for decorative applications, such as creating glass bottle lamps or porcelain crafts.

Conclusion: The Importance of Knowing the Minimum Diameter

The minimum diameter of hollow drill bits varies across industries and depends on the intended material to be drilled. For glass, tile, and ceramics, hollow drill bits can be as small as 5 mm, with brands like Bosch, Neiko, and DiamondSure leading the way. For metal annular cutters, the minimum diameter is generally 12 mm, as seen in products from Hougen, Evolution, and Bosch. For masonry and concrete, the minimum is usually 12 to 14 mm, with leading brands including Hilti, Makita, and Bosch. Knowing these specifications allows professionals to select the right tool for the job, ensuring efficiency, precision, and durability. The minimum diameter is not just a technical number but a critical factor that influences drilling speed, tool longevity, and material safety. By choosing the right hollow drill bit diameter and brand, users can achieve high-quality results across a wide spectrum of applications, whether it be in heavy construction, delicate glasswork, or industrial metal cutting.