Hexagonal handle positioning woodworking hole saws are essential tools in carpentry, woodworking, and DIY projects, designed to create precise, clean holes in various wood materials. The hexagonal (hex) handle design is critical for secure attachment to power tools like drills and impact drivers, minimizing slippage and maximizing torque transfer during operation. The “positioning” feature typically refers to a sharp, centered tip that helps align the hole saw accurately before cutting, reducing drift and ensuring hole precision. In this guide, we will explore prominent brands and their specific models of hexagonal handle positioning woodworking hole saws, detailing their specifications, features, applications, and performance characteristics.

Bosch, a globally renowned manufacturer of power tools and accessories, offers a range of high-quality hole saws tailored for woodworking. Their hexagonal handle positioning models are celebrated for durability, precision, and user-friendly design, making them popular among professionals and enthusiasts alike.

The Bosch HB2000 is a versatile set designed for general woodworking tasks, ideal for both softwoods (such as pine and cedar) and medium-density hardwoods (like oak and maple). The set includes multiple hole saw sizes, each featuring a hexagonal handle with a 1/4-inch hex shank, compatible with most standard drills and impact drivers. The shank is made from high-grade chrome-vanadium steel, ensuring strength and resistance to bending or warping under high torque.

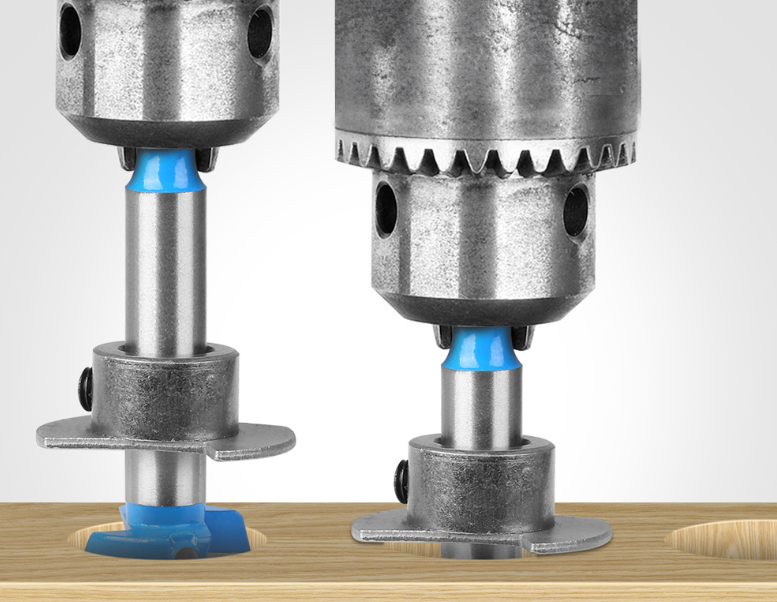

Each hole saw in the HB2000 set is constructed with a high-speed steel (HSS) cutting edge, heat-treated for enhanced hardness (up to 65 HRC) to maintain sharpness over extended use. The positioning tip is a standout feature: a pointed, hardened steel center pin that penetrates the wood first, stabilizing the saw and preventing skidding before the main cutting teeth engage. This tip is adjustable, allowing users to control the depth of initial penetration based on wood density.

The saw’s body features optimized chip evacuation slots—long, angled grooves that channel wood chips and dust away from the cutting area, reducing friction and heat buildup. This design not only keeps the cut clean but also extends the tool’s lifespan by minimizing wear on the teeth. The HB2000 set includes sizes ranging from 16mm (5/8 inch) to 54mm (2 1/8 inches), covering common hole diameters needed for tasks like installing door locks, electrical outlets, or pipe penetrations in wooden surfaces.

User feedback highlights the HB2000’s ease of use, with the hex handle providing a secure grip in tools, even during high-speed operation. The set also comes with a storage case, organizing the saws by size for quick access. While primarily designed for wood, the HSS teeth can also handle thin plywood and MDF, though Bosch recommends avoiding metal or abrasive materials to preserve the cutting edge.

For heavy-duty woodworking applications, especially with hardwoods, laminated woods, or composite materials, the Bosch HB5000 is a premium choice. Unlike the HB2000, the HB5000 features carbide-tipped cutting teeth, which offer superior wear resistance compared to HSS. Carbide is known for its ability to maintain sharpness when cutting dense or abrasive materials, making this model ideal for professional carpenters or those working on large-scale projects.

The hexagonal handle of the HB5000 is slightly larger, with a 3/8-inch hex shank, designed to fit more powerful drills and impact drivers, ensuring better torque transfer for tough cuts. The shank is coated with a black oxide finish, providing corrosion resistance and reducing friction during tool changes. The positioning tip is reinforced with carbide as well, ensuring it stays sharp even when drilling into hard, knotty wood, where standard steel tips might dull quickly.

The HB5000’s body is constructed from a durable alloy steel, with a reinforced shoulder where the shank meets the saw body to prevent breakage under heavy loads. The chip evacuation slots are wider and deeper than those on the HB2000, making them effective for clearing large volumes of wood chips generated when cutting thick hardwoods (up to 50mm in a single pass). Available sizes range from 22mm (7/8 inch) to 100mm (4 inches), catering to larger hole requirements, such as for pipe fittings or ventilation ducts in wooden structures.

Professionals praise the HB5000 for its longevity; many report that the carbide tips remain sharp after hundreds of cuts in hardwoods like teak or mahogany. The precision of the positioning tip is also noted, with minimal drift even when starting cuts on uneven or curved wooden surfaces.

DeWalt is synonymous with rugged, professional-grade tools, and their hexagonal handle positioning hole saws are no exception. Built to withstand rigorous job site conditions, DeWalt models prioritize durability, cutting speed, and accuracy, making them a top choice for contractors and industrial woodworkers.

The DeWalt DW1620 is a comprehensive kit designed for everyday woodworking tasks, combining affordability with reliable performance. The set includes 10 hole saws, each with a 1/4-inch hexagonal handle, compatible with most corded and cordless drills. The shank is forged from high-carbon steel, heat-treated for toughness, and features a knurled section near the base to enhance grip when manually inserting or removing the saw from the tool chuck.

The cutting edges of the DW1620 hole saws are made from bi-metal construction—HSS teeth bonded to a flexible alloy steel body. This design offers the best of both worlds: the HSS teeth provide sharpness and wear resistance, while the alloy steel body absorbs vibration, reducing fatigue during extended use. The positioning tip is a sharp, centered steel pin that ensures precise alignment, even when drilling at an angle (up to 15 degrees) in softwoods.

A key feature of the DW1620 is its “Quick-Change” system, though the hex handle itself is standard; the system refers to the ease with which the saws can be swapped out without tools, thanks to the secure hex shank fit. The chip evacuation slots are strategically angled to promote efficient dust removal, and the saw bodies are coated with a rust-resistant finish to protect against moisture and job site debris. Sizes in the kit range from 19mm (3/4 inch) to 64mm (2 1/2 inches), covering common applications like installing door knobs, cabinet hardware, or cable management holes.

Users appreciate the DW1620’s balance of performance and value, noting that the bi-metal teeth stay sharp longer than standard HSS in softwoods and plywood. The hex handle’s secure fit is also a highlight, with minimal slippage even when using high-torque drills on dense wood.

For demanding woodworking tasks, such as cutting through thick hardwoods, pressure-treated lumber, or even thin wooden boards with metal fasteners, the DeWalt DW1667 is engineered for heavy-duty use. This model features a 3/8-inch hexagonal handle, designed to handle the higher torque of professional-grade drills and impact drivers, reducing the risk of shank failure during tough cuts.

The DW1667’s cutting teeth are made from premium carbide, brazed onto a thick alloy steel body for maximum strength. Carbide is significantly harder than HSS, making this saw resistant to chipping and dulling when encountering knots, nails, or other impurities in wood. The positioning tip is a carbide-tipped center drill, which not only aligns the saw but also pre-drills a small pilot hole, reducing the force needed to start the cut and minimizing splintering on the wood’s surface.

The saw body is thicker than standard models, with reinforced walls to prevent warping during prolonged use. The chip evacuation slots are designed with a spiral pattern, which creates a centrifugal force that flings chips out of the cut area more effectively than straight slots, keeping the cutting zone cool and clear. The DW1667 is available in larger sizes, from 32mm (1 1/4 inches) to 152mm (6 inches), making it suitable for large holes required in structural woodworking, such as for beams, posts, or ventilation systems.

Contractors often note that the DW1667 is a workhorse, capable of cutting through 2x4s and thicker hardwoods with minimal effort. The hex handle’s robust construction is praised for withstanding daily use on job sites, and the carbide tips require minimal sharpening compared to HSS models.

Milwaukee Tool is known for innovation and durability, and their hexagonal handle positioning hole saws are designed with advanced features to enhance productivity and precision. Targeting professional users, Milwaukee models often incorporate proprietary technologies to improve cutting speed and tool life.

The Milwaukee 48-22-4100 is a professional-grade set designed for high-volume woodworking applications, such as cabinetry, furniture making, and construction. The set includes 7 hole saws with 1/4-inch hexagonal handles, crafted from forged steel for exceptional strength. The shanks feature a “Secure-Grip” hex design, with slightly rounded edges that fit tightly into drill chucks, reducing play and ensuring maximum torque transfer.

The cutting teeth of the 48-22-4100 are made from precision-ground HSS, with a special tooth geometry that Milwaukee calls “Aggressive Cutting Action.” This design features angled teeth with deeper gullets, allowing for faster material removal and smoother cuts in both softwoods and hardwoods. The positioning tip is a self-centering steel pin with a sharp point, which penetrates quickly and holds its position even when drilling at high speeds (up to 3,000 RPM).

A standout feature of this set is the “Anti-Seize” coating on the saw bodies, which reduces friction between the saw and the wood, preventing the tool from getting stuck in deep cuts. The chip evacuation slots are extra-wide and curved, designed to channel chips away from the cutting area efficiently, even when cutting thick materials (up to 75mm). The set includes sizes from 25mm (1 inch) to 76mm (3 inches), covering a range of common hole sizes for hardware installation and woodworking joinery.

Professionals highlight the 48-22-4100’s cutting speed, noting that it drills holes up to 30% faster than comparable models, thanks to the aggressive tooth design. The hex handle’s secure fit is also a plus, with no slippage reported even during extended use with high-powered drills.

For cutting through abrasive wood materials, such as pressure-treated lumber, OSB (oriented strand board), or wood composite decking, the Milwaukee 48-22-4270 is equipped with carbide-grit cutting edges. Unlike traditional teeth, carbide grit is bonded to the saw’s edge, providing exceptional resistance to wear when cutting materials that would quickly dull HSS or even standard carbide teeth.

The hexagonal handle of the 48-22-4270 is a 3/8-inch shank, made from high-strength alloy steel with a black oxide finish for corrosion resistance. The handle features a flanged base that prevents the saw from being pulled too far into the drill chuck, ensuring consistent positioning during cuts. The positioning tip is a carbide-tipped drill bit, which not only aligns the saw but also creates a pilot hole that guides the carbide grit edge, ensuring a clean, precise start.

The saw body is constructed from a thick-walled alloy steel, designed to withstand the high forces generated when cutting through dense, abrasive materials. The chip evacuation system includes both slots and small ports near the base of the saw, which work together to expel fine dust and debris, preventing clogging that can slow cutting speed. The 48-22-4270 is available in sizes from 38mm (1 1/2 inches) to 127mm (5 inches), making it suitable for heavy-duty applications like deck building, outdoor furniture construction, or cutting holes in composite siding.

Users report that the carbide-grit edge of the 48-22-4270 lasts significantly longer than standard teeth when cutting pressure-treated wood, which contains chemicals that can accelerate wear. The hex handle’s stability is also praised, with no wobble during high-torque cuts, ensuring hole roundness and accuracy.

Makita, a leader in power tools and accessories, offers hexagonal handle positioning hole saws known for precision engineering and ergonomic design. Their models are designed to work seamlessly with Makita drills but are compatible with most standard tools, appealing to both professionals and DIY users.

The Makita B-65399 is a compact, user-friendly set ideal for home woodworking projects and light professional use. The set includes 6 hole saws with 1/4-inch hexagonal handles, made from high-quality carbon steel with a polished finish to reduce friction and resist corrosion. The hex shank is designed for a snug fit in drill chucks, minimizing slippage and ensuring efficient torque transfer.

The cutting teeth of the B-65399 are made from HSS, heat-treated to a hardness of 62-64 HRC for a sharp, durable edge. The teeth are arranged in a alternating pattern, which reduces vibration and produces smoother cuts in softwoods like pine, fir, and spruce. The positioning tip is a centered steel pin with a conical shape, which helps align the saw quickly and prevents drifting, even for users with less experience.

The saw bodies feature narrow but effective chip evacuation slots, designed to clear debris without adding unnecessary weight to the tool. This makes the B-65399 lightweight and easy to control, reducing user fatigue during extended use. The set includes sizes from 16mm (5/8 inch) to 51mm (2 inches), covering common household applications like installing shelf brackets, curtain rods, or electrical boxes in wooden walls.

DIY enthusiasts appreciate the B-65399’s affordability and ease of use, noting that the hex handle fits securely in both corded and cordless drills. The HSS teeth stay sharp for dozens of cuts in softwoods, making it a reliable choice for small projects.

For professional woodworkers needing a tool that can handle hardwoods, plywood, and even thin layers of veneer, the Makita XPS01Z is a high-performance option. This model features a 3/8-inch hexagonal handle, made from forged alloy steel for strength, and compatible with Makita’s line of high-torque drills and impact drivers.

The XPS01Z’s cutting edge is equipped with carbide tips, brazed onto a rigid alloy steel body for maximum durability. Carbide tips are ideal for cutting hardwoods like walnut, cherry, and mahogany, as they resist wear and maintain sharpness even when encountering dense grain patterns. The positioning tip is a carbide drill bit integrated into the center of the saw, which pre-drills a pilot hole to guide the cutting teeth, ensuring precise hole placement and reducing splintering on the wood’s surface.

The saw body features a “Vibration-Dampening” design, with a reinforced collar where the shank meets the body to absorb shock and reduce hand fatigue. The chip evacuation slots are wider at the top and narrower at the base, creating a funnel effect that directs chips away from the cutting area efficiently. The XPS01Z is available in sizes from 25mm (1 inch) to 76mm (3 inches), making it suitable for professional applications like furniture making, cabinetry, and custom woodworking.

Professionals praise the XPS01Z for its precision, noting that the carbide tips produce clean, splinter-free cuts in hardwoods, which is crucial for visible woodworking projects. The hex handle’s compatibility with Makita’s high-powered tools is also a plus, allowing for fast, efficient cutting even in thick materials.

Irwin Tools has a long history of producing reliable cutting tools, and their hexagonal handle positioning hole saws are designed with a focus on durability and versatility. Their models cater to both professional and consumer markets, offering a balance of performance and value.

The Irwin 3080002 is a popular set among DIYers and occasional woodworkers, combining affordability with solid performance. The set includes 8 hole saws with 1/4-inch hexagonal handles, made from carbon steel with a black oxide coating to resist rust and corrosion. The hex shank is designed for universal fit, working with most standard drills and impact drivers.

The cutting teeth of the 3080002 are made from HSS, with a “ProTouch” tooth design that features a slightly rounded edge to reduce splintering in softwoods. The teeth are sharpened to a fine point, allowing for quick penetration and smooth cutting in materials like pine, plywood, and MDF. The positioning tip is a centered steel pin, which is easy to align and provides stable guidance during the initial stages of cutting.

The saw bodies are lightweight, with basic chip evacuation slots that clear debris adequately for light to moderate use. The set includes sizes from 19mm (3/4 inch) to 64mm (2 1/2 inches), making it suitable for a range of home projects, from installing door locks to building wooden furniture.

Users note that the 3080002 is a reliable choice for occasional use, with the hex handle providing a secure fit in most drills. While the HSS teeth may dull faster in hardwoods, they perform well in softwoods and are easy to sharpen when needed.

For heavy-duty woodworking tasks, the Irwin 1887781 is built to withstand tough conditions, featuring carbide-tipped teeth and a robust hexagonal handle. This model has a 3/8-inch hex shank, made from high-strength alloy steel, designed to handle the torque of professional drills and impact drivers, making it suitable for contractors and industrial users.

The 1887781’s cutting teeth are made from premium carbide, bonded to a thick-walled steel body for maximum strength. Carbide tips excel at cutting through hardwoods, pressure-treated lumber, and even wood with embedded nails, as they resist chipping and wear. The positioning tip is a carbide drill bit that ensures precise alignment, even in dense or uneven wood surfaces.

The saw body features a “Speed Slot” chip evacuation system, with extra-wide slots that allow for rapid debris removal, reducing heat buildup and keeping the cutting area cool. This design also makes it easy to remove stuck chips from the saw body, minimizing downtime. The 1887781 is available in sizes from 25mm (1 inch) to 102mm (4 inches), catering to large hole requirements in structural woodworking and construction.

Contractors praise the 1887781 for its durability, noting that the carbide tips remain sharp after hundreds of cuts in hardwoods and pressure-treated lumber. The hex handle’s secure fit and the saw’s overall ruggedness make it a dependable tool for demanding job site conditions.

Hexagonal handle positioning woodworking hole saws are indispensable tools for achieving precise, clean holes in wood, with their hex handle design ensuring secure attachment and efficient torque transfer, and their positioning tips guaranteeing accurate alignment. Brands like Bosch, DeWalt, Milwaukee, Makita, and Irwin offer a range of models tailored to different needs, from lightweight sets for DIY projects to heavy-duty carbide-tipped options for professional use.

When selecting a model, consider factors such as the type of wood (softwood vs. hardwood), hole size requirements, and frequency of use. HSS models are ideal for softwoods and occasional use, while carbide-tipped saws are better suited for hardwoods, abrasive materials, and heavy-duty applications. The hexagonal handle size (1/4-inch or 3/8-inch) should match the capabilities of your power tool to ensure compatibility and performance.

By understanding the features and specifications of these models, woodworkers can choose the right hexagonal handle positioning hole saw to enhance precision, productivity, and tool longevity in their projects. Whether you’re a professional contractor or a DIY enthusiast, investing in a quality hole saw from a reputable brand will ensure consistent, reliable results for years to come.