Are Scraper Drill Bits Currently the Most Widely Used Drill Bits?

The global drilling industry has witnessed a diverse array of drill bit technologies evolving over the past century, each tailored to specific geological formations, operational requirements, and economic considerations. Among these, scraper drill bits—particularly those incorporating Polycrystalline Diamond Compact (PDC) technology—have emerged as a dominant force in modern drilling operations. This analysis explores the prevalence, technological advancements, and market adoption of scraper drill bits, focusing on leading brands, model specifications, and their comparative advantages over alternative designs.

1. The Rise of Scraper Drill Bits: Technological Foundations and Market Dominance

Scraper drill bits, characterized by their fixed-blade cutting structures and synthetic diamond cutters, represent a paradigm shift from traditional roller cone and drag bit designs. The core innovation lies in the integration of PDC cutters—layers of synthetic diamond particles sintered onto tungsten carbide substrates—which provide unparalleled hardness, wear resistance, and thermal stability. Unlike roller cone bits, which rely on rolling elements to crush rock, scraper bits shear formations through a scraping or plowing motion, enabling higher rates of penetration (ROP) and extended bit life in medium-to-hard formations.

1.1 Market Penetration and Industry Adoption

According to industry reports, PDC scraper bits account for over 60% of the global drill bit market, with their dominance particularly pronounced in oil and gas exploration, geothermal drilling, and mining applications. For instance, in the Kinsevere copper mine (Democratic Republic of Congo), operators reported a 40% increase in drilling efficiency after switching from roller cone bits to PDC scraper designs. Similarly, in the Permian Basin (United States), PDC bits reduced drilling time by 25% while lowering non-productive time (NPT) associated with bit changes.

The shift toward scraper bits is driven by their cost-effectiveness in deepwater and extended-reach drilling, where rig day rates exceed $500,000. A single PDC bit can drill multiple intervals, whereas roller cone bits may require frequent replacements due to bearing failures or cutter wear. For example, Schlumberger’s StingBlade conical diamond element (CDE) bits have demonstrated 300% longer life in abrasive sandstone formations compared to conventional PDC designs.

2. Leading Brands and Model Specifications: A Comparative Analysis

The scraper drill bit market is highly consolidated, with a handful of manufacturers dominating both premium and mid-tier segments. Below is a detailed examination of key brands, their flagship models, and technological differentiators:

2.1 Schlumberger (Smith Bits)

Model: StingBlade CDE Series

- Cutting Structure: Conical diamond elements (CDE) arranged in a spiral pattern to optimize force distribution and reduce vibration.

- Applications: Hard and abrasive formations, including shale, sandstone, and carbonate reservoirs.

- Performance Metrics:

- ROP improvement: Up to 50% versus conventional PDC bits in 12,000-ft lateral sections.

- Bit life: 300% longer in high-stress environments due to reinforced cutter substrates.

- Hydraulics: Dual-flow channels enhance chip evacuation, reducing balling in water-based muds.

Model: AxeBlade Ridged Diamond Element Bits

- Cutting Structure: Ridged diamond elements (RDE) with micro-textured surfaces to enhance shear efficiency.

- Applications: Interbedded formations with alternating soft and hard layers.

- Performance Metrics:

- ROP: 20% faster in 10,000-psi overbalanced drilling conditions.

- Steerability: Improved directional control in horizontal wells due to reduced torque fluctuations.

2. Baker Hughes (Hughes Christensen)

Model: Kymera XT Hybrid Bit

- Cutting Structure: Combination of PDC cutters and tungsten carbide inserts (TCI) for multi-stage rock breaking.

- Applications: Transitional formations with varying hardness (e.g., limestone-shale interfaces).

- Performance Metrics:

- Versatility: Reduces the need for bit trips by 30% in mixed-lithology wells.

- Durability: 50% longer life than standard PDC bits in 15,000-psi environments.

Model: TerrAdapt Adaptive Drilling Bit

- Cutting Structure: Self-adjusting cutters that reorient under load to maintain optimal attack angles.

- Applications: Unconventional reservoirs with unpredictable rock properties.

- Performance Metrics:

- ROP: 15% higher in 8,000-ft laterals with high dogleg severity.

- Stability: 40% reduction in lateral vibration, minimizing drillstring fatigue.

2. Halliburton (Sperry Drilling)

Model: NeoReam Reaming System

- Cutting Structure: Expandable PDC cutters for simultaneous drilling and reaming operations.

- Applications: Underreaming wells to enlarge boreholes for casing installation.

- Performance Metrics:

- Efficiency: Single-pass reaming reduces drilling time by 50% versus conventional methods.

- Precision: Maintains borehole gauge within ±0.5 inches in 12¼-in. holes.

Model: MicroScope High-Definition Imaging Bit

- Cutting Structure: Integrated sensors for real-time downhole data acquisition.

- Applications: Geosteering and formation evaluation in complex well trajectories.

- Performance Metrics:

- Data resolution: 10x higher than traditional measurement-while-drilling (MWD) tools.

- Decision speed: Enables immediate adjustments to drilling parameters based on rock properties.

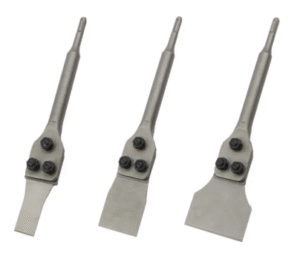

2. Glorytek Industry (Beijing) Co., Ltd.

Model: Tri-Wing Scraper Bit PDC Drag Bits

- Cutting Structure: Three-winged design with 19mm PDC cutters arranged in a spiral pattern.

- Applications: Water well drilling, HDD (Horizontal Directional Drilling), and oil exploration.

- Performance Metrics:

- ROP: 2–80 m/h depending on rock strength (e.g., 20 m/h in medium-hard limestone).

- Durability: Steel or matrix body options for corrosion resistance in saline environments.

- Hydraulics: Six nozzles for optimal mud flow, reducing bit balling in clay-rich formations.

Model: 75# 3-Wing Non-Core PDC Drill Bit

- Cutting Structure: Non-coring design with balanced cutter layout for stable drilling.

- Applications: Soft to medium-hard formations (e.g., sandstone, shale, and coal seams).

- Performance Metrics:

- Aggressiveness: Unique backrake angle reduces torque by 15% while increasing ROP.

- Wear Resistance: Duraset gauge material extends bit life by 40% in abrasive conditions.

3. Scraper Bits vs. Alternative Designs: A Performance Comparison

To contextualize the dominance of scraper bits, it is essential to evaluate their performance against competing technologies:

3.1 Roller Cone Bits

- Advantages:

- Effective in soft to medium formations (e.g., clay, sand).

- Lower initial cost for small-diameter bits (e.g., 6½-in. and below).

- Disadvantages:

- Limited life in hard formations due to bearing failures.

- Lower ROP in deep wells (e.g., <5,000 ft) where weight-on-bit (WOB) exceeds 50,000 lbs.

3.2 Diamond Bits (Impregnated and Surface-Set)

- Advantages:

- Superior durability in ultra-hard formations (e.g., granite, basalt).

- Ideal for coring operations where sample integrity is critical.

- Disadvantages:

- Slow ROP in soft formations due to low aggressiveness.

- High cost (e.g., $10,000+ per bit) limits use to specialized applications.

3.3 Hybrid Bits (PDC-TCI Combinations)

- Advantages:

- Versatility in transitional formations (e.g., shale-sandstone interfaces).

- Reduced bit trips compared to single-technology designs.

- Disadvantages:

- Compromised performance in extreme hardness or softness.

- Higher complexity increases failure risk.

4. Future Trends: Innovations Driving Scraper Bit Evolution

The scraper bit market is poised for transformative growth, driven by advancements in materials science, automation, and sustainability:

4.1 Nanotechnology-Enhanced Cutters

Researchers at Sichuan University demonstrated that pulsed magnetic field treatment can increase the hardness of PDC cutters by up to 116% and reduce wear area by 38% after drilling 12,000 bores. Such treatments could extend bit life to 500+ hours in 20,000-psi environments.

4.2 AI-Optimized Cutting Structures

Baker Hughes’ TerrAdapt bit uses machine learning algorithms to adjust cutter angles in real time based on rock feedback. Early trials in the Marcellus Shale showed a 22% ROP improvement versus static designs.

4.3 Eco-Friendly Materials

Glorytek’s matrix body bits, made from recycled tungsten carbide, reduce carbon footprint by 30% compared to steel-bodied alternatives. This aligns with industry-wide goals to cut drilling-related emissions by 50% by 2030.

5. Conclusion: The Indisputable Leadership of Scraper Drill Bits

Scraper drill bits, particularly those leveraging PDC technology, have cemented their status as the most widely used drilling tools across the energy, mining, and infrastructure sectors. Their superior ROP, durability, and adaptability to diverse formations make them indispensable in high-cost drilling environments. Brands like Schlumberger, Baker Hughes, and Glorytek continue to push technological boundaries, introducing bits capable of drilling deeper, faster, and more sustainably than ever before. While alternative designs retain niche applications, the scraper bit’s cost-benefit ratio ensures its dominance for the foreseeable future. As the industry prioritizes efficiency and environmental stewardship, innovations in cutter materials, automation, and eco-design will further solidify the scraper bit’s position as the cornerstone of modern drilling operations.