When it comes to metalworking, the 4 1/2 angle grinder stands as a versatile and indispensable tool, and at the heart of its cutting capabilities lies the metal cutting blade. These blades, designed specifically for slicing through various metals—from steel and stainless steel to aluminum and cast iron—come in a wide array of brands, models, and configurations, each tailored to specific applications, material thicknesses, and user preferences. In this extensive guide, we will delve into the world of 4 1/2 angle grinder metal cutting blades, exploring the top brands, their standout models, key features, performance metrics, and what makes each option suitable for different tasks. Whether you’re a professional fabricator, a DIY enthusiast, or someone looking to equip their workshop with the best tools, this guide will provide you with the detailed information needed to make an informed decision.

Understanding 4 1/2 Angle Grinder Metal Cutting Blades: Basics and Key Terms

Before diving into specific brands and models, it’s essential to understand the fundamental aspects of 4 1/2 angle grinder metal cutting blades. The term “4 1/2” refers to the blade’s diameter, measured in inches, which is a standard size for compact angle grinders, making them ideal for tight spaces, precision cuts, and portable use. These blades are typically made from abrasive materials or have hardened teeth, designed to cut through metal by abrasion or mechanical shearing. Key specifications to consider include the blade’s arbor size (the hole in the center that fits the grinder’s spindle), which is usually 7/8 inch or 5/8 inch for most 4 1/2 models, though some may have adapters to fit different grinders. Additionally, the blade’s thickness, grit size (for abrasive blades), and maximum RPM (revolutions per minute) rating are critical factors, as they determine the blade’s durability, cutting speed, and safety—using a blade with a lower RPM rating than the grinder’s maximum speed can lead to dangerous failures.

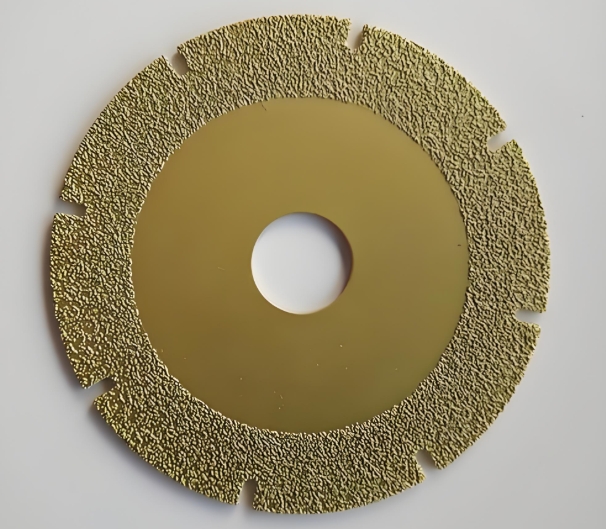

Abrasive metal cutting blades, often made from aluminum oxide, zirconia alumina, or silicon carbide, work by grinding away at the metal, generating heat in the process. These blades are suitable for general-purpose cutting, especially on ferrous metals like steel, but they tend to wear down faster than other types, particularly when used on hard or thick materials. On the other hand, diamond-tipped blades, though more expensive, offer exceptional durability and are ideal for cutting hard metals, including stainless steel and cast iron, as well as non-ferrous metals like aluminum. Carbide-tipped blades, with their hard carbide teeth, are another option, providing clean, fast cuts on a range of metals and offering a longer lifespan than abrasive blades. Each type has its pros and cons, and the choice depends on the specific metal being cut, the desired finish, and the frequency of use.

Top Brands in 4 1/2 Angle Grinder Metal Cutting Blades

The market for 4 1/2 angle grinder metal cutting blades is dominated by several reputable brands, each known for their commitment to quality, innovation, and performance. These brands have earned the trust of professionals and hobbyists alike through years of consistent delivery of reliable products. Below, we will explore each brand in detail, highlighting their most popular models, unique features, and the applications they excel in.

DEWALT: A Leader in Power Tool Accessories

DEWALT, a name synonymous with durability and performance in power tools, offers a range of 4 1/2 angle grinder metal cutting blades designed to meet the demands of professionals. One of their standout models is the DEWALT DW8062 4-1/2-Inch by 7/8-Inch Metal Cutting Wheel. This abrasive wheel is constructed with zirconia alumina, a material known for its self-sharpening properties and ability to maintain cutting efficiency even as the blade wears. The DW8062 features a 7/8-inch arbor, making it compatible with most standard 4 1/2 angle grinders, and has a maximum RPM rating of 13,300, which is suitable for high-speed grinders commonly used in industrial settings.

What sets the DW8062 apart is its reinforced design, which includes a fiberglass mesh backing that enhances durability and reduces the risk of breakage during heavy use. This makes it ideal for cutting through thick steel, angle iron, and rebar, where the blade is subjected to significant stress. The blade’s thickness of 0.045 inches strikes a balance between cutting speed and precision, allowing for fast cuts without excessive material loss. Users praise the DW8062 for its long lifespan, even when used continuously on tough metals, and its ability to produce clean cuts with minimal burring, reducing the need for post-cutting finishing work.

Another popular model from DEWALT is the DEWALT DW8032 4-1/2-Inch by 5/8-Inch Metal Cutting Wheel. This blade is designed with a 5/8-inch arbor, catering to grinders with smaller spindles, and is also made from zirconia alumina for high performance. It has a maximum RPM of 13,200, making it suitable for both professional and DIY use. The DW8032 is slightly thicker than the DW8062, at 0.062 inches, which provides added stability for cutting through medium to thick metals, such as steel pipes and structural steel. Its reinforced construction ensures safety during use, and its aggressive cutting action allows for quick material removal, making it a favorite among contractors and fabricators who need to complete jobs efficiently.

DEWALT also offers diamond-tipped options, such as the DEWALT DWA8904 4-1/2-Inch Diamond Metal Cutting Blade. This blade features a continuous rim with industrial-grade diamonds embedded in a metal matrix, designed for cutting through hard metals like stainless steel, cast iron, and hardened steel. The 7/8-inch arbor and maximum RPM of 13,300 make it compatible with most grinders, and its thin kerf (0.080 inches) ensures precise cuts with minimal material waste. The DWA8904 is particularly valued for its longevity—diamond blades can last up to 50 times longer than abrasive blades when cutting hard metals—and its ability to maintain a cool cutting temperature, reducing the risk of warping the material being cut. This makes it an excellent investment for professionals who frequently work with tough metals and want to minimize blade replacement costs.

Makita: Precision and Reliability for Metalworking

Makita, a Japanese brand renowned for its high-quality power tools and accessories, offers a diverse lineup of 4 1/2 angle grinder metal cutting blades that combine precision with rugged performance. One of their most popular abrasive blades is the Makita 741411-6 4-1/2-Inch by 7/8-Inch Metal Cutting Wheel. This blade is crafted from premium zirconia alumina, selected for its ability to deliver fast, smooth cuts on a variety of ferrous metals, including carbon steel and mild steel. The 7/8-inch arbor ensures compatibility with most standard grinders, and the blade has a maximum RPM rating of 13,200, making it suitable for high-speed applications.

The Makita 741411-6 features a thin design, with a thickness of 0.045 inches, which allows for precise cuts and reduces heat buildup during use—an important factor when working with metals that are prone to warping. The blade’s reinforced fiberglass backing provides added strength, preventing breakage even under heavy loads, and its uniform grit distribution ensures consistent cutting performance throughout its lifespan. Users report that this blade excels in cutting thin to medium-gauge metal sheets, metal studs, and pipes, producing clean edges that require little to no deburring. Its long-lasting performance also makes it a cost-effective choice for both professionals and DIYers.

For those needing a blade for non-ferrous metals like aluminum, Makita offers the Makita B-65170 4-1/2-Inch by 7/8-Inch Aluminum Cutting Wheel. This specialized blade is designed with a silicon carbide abrasive, which is less aggressive than zirconia alumina and less likely to clog when cutting soft metals like aluminum, copper, and brass. Clogging, which occurs when metal particles adhere to the blade’s surface, can reduce cutting efficiency and cause overheating, so the B-65170’s formulation is crucial for maintaining performance on non-ferrous materials. The blade has a 7/8-inch arbor, a maximum RPM of 13,200, and a thickness of 0.062 inches, providing stability for cutting through aluminum bars, tubing, and sheets. Its reinforced construction ensures safety, and its ability to produce smooth, burr-free cuts on aluminum makes it a top choice for automotive enthusiasts, plumbers, and metalworkers who frequently work with non-ferrous metals.

Makita’s diamond cutting blades are also highly regarded, with the Makita A-97674 4-1/2-Inch Diamond Metal Cutting Blade standing out as a premium option. This blade features a segmented rim with high-quality diamonds, designed for fast cutting through stainless steel, cast iron, and other hard metals. The 7/8-inch arbor and maximum RPM of 13,300 make it compatible with most grinders, and its thin kerf (0.078 inches) allows for precise cuts with minimal material loss. The segmented design helps to dissipate heat and remove debris, reducing the risk of overheating and ensuring consistent performance. Professionals in the metal fabrication and construction industries often choose the A-97674 for its durability and ability to handle heavy-duty cutting tasks with ease.

Bosch: Innovation and Efficiency in Cutting Blades

Bosch, a global leader in engineering and technology, offers a range of 4 1/2 angle grinder metal cutting blades that blend innovation with practicality, designed to meet the needs of both professionals and DIY users. One of their flagship models is the Bosch DCB450 4-1/2-Inch by 7/8-Inch Metal Cutting Wheel. This abrasive blade is made from a proprietary zirconia alumina blend, optimized for fast cutting and long life on ferrous metals. The 7/8-inch arbor ensures compatibility with most grinders, and the blade has a maximum RPM rating of 13,200, making it suitable for high-speed applications.

The DCB450 features a unique “Power Sharp” design, which ensures that the blade maintains its sharpness throughout its lifespan, reducing the need for frequent replacements. Its thin profile (0.045 inches) allows for quick, precise cuts, making it ideal for cutting metal studs, conduit, and sheet metal. The blade’s reinforced fiberglass backing provides added strength and safety, and its balanced construction minimizes vibration during use, reducing user fatigue—a key benefit for professionals who spend hours working with their grinders. Users praise the DCB450 for its consistent performance, even when cutting through thick or hardened steel, and its ability to produce clean cuts with minimal sparking, which is a plus for worksites where excessive sparks could be a hazard.

For cutting stainless steel, Bosch offers the Bosch DCB451 4-1/2-Inch by 7/8-Inch Stainless Steel Cutting Wheel. This specialized blade is formulated with a chrome oxide abrasive, which is less reactive with stainless steel than other abrasives, reducing the risk of contamination and ensuring clean cuts. Stainless steel is notoriously difficult to cut due to its hardness and tendency to work-harden, but the DCB451’s design addresses these challenges, with a thin profile (0.045 inches) that minimizes heat buildup and a reinforced backing for durability. The blade has a maximum RPM of 13,200 and a 7/8-inch arbor, making it compatible with standard grinders. It is particularly popular among metalworkers who specialize in stainless steel fabrication, as it produces smooth, precise cuts that require little post-processing.

Bosch also offers a carbide-tipped option, the Bosch TCW45 4-1/2-Inch Carbide Tipped Metal Cutting Blade. This blade features carbide teeth brazed onto a steel core, designed for fast, clean cuts on a variety of metals, including steel, aluminum, and copper. The 7/8-inch arbor and maximum RPM of 12,000 make it suitable for use with most 4 1/2 angle grinders, and its 0.090-inch thickness provides stability for cutting through thicker materials. The carbide teeth are engineered to stay sharp longer than abrasive blades, making the TCW45 a cost-effective choice for users who cut metal frequently. The blade’s tooth geometry is optimized for efficient chip removal, reducing heat and preventing clogging, and its anti-vibration design ensures smooth operation. This makes it a versatile option for both professional and DIY projects, from cutting metal pipes to fabricating metal brackets.

Milwaukee Tool: Heavy-Duty Performance for Professionals

Milwaukee Tool, known for its rugged, professional-grade tools, offers 4 1/2 angle grinder metal cutting blades designed to withstand the toughest job site conditions. Their Milwaukee 48-80-4025 4-1/2-Inch by 7/8-Inch Metal Cutting Wheel is a top choice among professionals in construction, fabrication, and automotive repair. This abrasive blade is made from premium zirconia alumina, selected for its aggressive cutting action and long life, even when used on thick steel and other hard metals. The 7/8-inch arbor and maximum RPM of 13,300 ensure compatibility with high-speed grinders, and the blade’s reinforced fiberglass backing provides exceptional durability, reducing the risk of breakage during heavy use.

The 48-80-4025 features a thin design (0.045 inches) that allows for fast cuts with minimal material waste, and its uniform grit distribution ensures consistent performance throughout its lifespan. What sets this blade apart is Milwaukee’s “Red Latch” technology, which ensures a secure fit on the grinder, reducing the risk of slippage during operation—a critical safety feature for high-speed tools. Users report that the 48-80-4025 excels in cutting rebar, angle iron, and structural steel, delivering reliable performance even in demanding environments. Its ability to maintain cutting efficiency without overheating makes it a favorite among professionals who need to complete jobs quickly and efficiently.

For cutting stainless steel, Milwaukee offers the Milwaukee 48-80-4035 4-1/2-Inch by 7/8-Inch Stainless Steel Cutting Wheel. This specialized blade is formulated with a ceramic abrasive that is highly effective on stainless steel, reducing heat buildup and preventing work-hardening. The blade has a 7/8-inch arbor, a maximum RPM of 13,300, and a thin profile (0.045 inches) for precise cuts. Its reinforced construction ensures safety, and its aggressive cutting action allows for fast material removal, even on thick stainless steel sheets and pipes. Professionals who work with stainless steel regularly appreciate the 48-80-4035 for its durability and ability to produce clean, burr-free cuts, which saves time on finishing work.

Milwaukee also offers a diamond blade, the Milwaukee 48-80-5125 4-1/2-Inch Diamond Metal Cutting Blade, designed for extreme durability and performance on the hardest metals. This blade features a continuous rim with high-density diamond segments, engineered to cut through cast iron, hardened steel, and stainless steel with ease. The 7/8-inch arbor and maximum RPM of 13,300 make it compatible with standard grinders, and its thin kerf (0.080 inches) ensures precise cuts with minimal material loss. The diamond segments are bonded to a steel core using a proprietary process that enhances adhesion, ensuring long life even under heavy use. This blade is a favorite among professionals who need to cut hard metals on a regular basis, as it outlasts abrasive blades by a significant margin, reducing downtime and replacement costs.

Ingersoll Rand: Precision and Durability for Industrial Use

Ingersoll Rand, a leader in industrial tools and equipment, offers 4 1/2 angle grinder metal cutting blades designed for precision and durability in industrial settings. Their Ingersoll Rand 38468751 4-1/2-Inch by 7/8-Inch Metal Cutting Wheel is a high-performance abrasive blade made from a premium zirconia alumina blend, optimized for cutting through steel, iron, and other ferrous metals. The 7/8-inch arbor and maximum RPM of 13,200 make it compatible with most industrial-grade grinders, and its reinforced construction ensures safety and longevity, even in continuous use.

The 38468751 features a unique grain structure that provides fast cutting action while maintaining a consistent finish, reducing the need for post-cutting processing. Its thin profile (0.045 inches) allows for precise cuts, making it ideal for intricate metalworking tasks, and its balanced design minimizes vibration, reducing user fatigue during long work sessions. Industrial fabricators and machinists often choose this blade for its reliability and ability to handle high-volume cutting jobs with consistent performance.

For cutting non-ferrous metals, Ingersoll Rand offers the Ingersoll Rand 38468752 4-1/2-Inch by 7/8-Inch Non-Ferrous Cutting Wheel. This blade is formulated with silicon carbide abrasive, which is gentle enough to avoid clogging when cutting aluminum, copper, and brass, while still providing efficient cutting action. The 7/8-inch arbor and maximum RPM of 13,200 ensure compatibility with standard grinders, and its reinforced backing provides durability. The blade’s design minimizes heat buildup, preventing warping in soft metals, and its uniform grit distribution ensures smooth cuts. This makes it a valuable tool for industries that work extensively with non-ferrous metals, such as aerospace and electronics manufacturing.

Metabo: German Engineering for Superior Cutting

Metabo, a German brand known for its precision engineering, offers 4 1/2 angle grinder metal cutting blades that combine German quality with advanced technology. Their Metabo 628155000 4-1/2-Inch by 7/8-Inch Metal Cutting Wheel is a premium abrasive blade designed for fast, clean cuts on ferrous metals. Made from high-grade zirconia alumina, this blade features a unique bonding agent that ensures the abrasive grains stay sharp longer, extending the blade’s lifespan. The 7/8-inch arbor and maximum RPM of 13,300 make it compatible with high-speed grinders, and its reinforced fiberglass mesh backing provides exceptional strength, meeting strict safety standards for industrial use. The 628155000 has a thin kerf of 0.045 inches, allowing for quick material removal and precise cuts, making it ideal for cutting metal pipes, angle iron, and sheet metal in both professional and industrial settings. Users appreciate its consistent performance, even when subjected to heavy loads, and its ability to produce minimal burrs, which reduces the need for time-consuming finishing work. The blade’s balanced construction also helps to minimize vibration, making it more comfortable to use for extended periods, a feature that is highly valued by tradespeople who rely on their tools day in and day out.

Metabo also offers a specialized blade for stainless steel, the Metabo 628156000 4-1/2-Inch by 7/8-Inch Stainless Steel Cutting Wheel. This blade is formulated with a high-performance abrasive blend that is specifically designed to cut through stainless steel without causing contamination or excessive heat buildup, which can compromise the metal’s integrity. Stainless steel cutting requires precision and care to avoid work hardening, and the 628156000 addresses this with its thin profile (0.045 inches) that reduces friction and heat, and its reinforced backing that ensures durability even when cutting through thick or hardened stainless steel. The blade has a maximum RPM of 13,300 and a 7/8-inch arbor, making it compatible with most standard grinders, and its aggressive cutting action allows for efficient material removal, saving time on the job. Professionals in the food processing, medical equipment, and architectural metalworking industries often turn to this blade for its ability to produce clean, precise cuts that meet strict quality standards.

For those seeking a diamond-tipped option, Metabo’s Metabo 628160000 4-1/2-Inch Diamond Metal Cutting Blade is a top-tier choice. This blade features a continuous rim embedded with high-quality diamonds, designed to cut through the toughest metals, including cast iron, hardened steel, and tool steel. The diamond particles are bonded to a sturdy steel core using a proprietary process that ensures long-lasting performance, even under heavy use, and the blade’s thin kerf (0.080 inches) allows for precise cuts with minimal material waste. The 7/8-inch arbor and maximum RPM of 13,300 make it compatible with most 4 1/2 angle grinders, and its design allows for cool cutting, reducing the risk of warping the material being worked on. This blade is particularly popular among machinists and metal fabricators who need to make precise cuts on hard metals and want a blade that will last through multiple projects, reducing the need for frequent replacements.

Black & Decker: Affordable Quality for DIY Enthusiasts

Black & Decker, a household name in power tools and accessories, offers 4 1/2 angle grinder metal cutting blades that provide reliable performance at an affordable price, making them ideal for DIY enthusiasts and occasional users. One of their most popular models is the Black & Decker 74-666 4-1/2-Inch by 7/8-Inch Metal Cutting Wheel. This abrasive blade is made from aluminum oxide, a cost-effective abrasive that works well for cutting ferrous metals like mild steel and iron. The 7/8-inch arbor ensures compatibility with most standard 4 1/2 angle grinders, and the blade has a maximum RPM of 11,000, making it suitable for use with lower-speed grinders commonly found in home workshops.

The 74-666 features a reinforced fiberglass backing for safety, and its 0.062-inch thickness provides stability for cutting through medium-gauge metal, such as steel pipes and sheet metal. While it may not last as long as premium zirconia alumina blades, it offers excellent value for money, making it a great choice for DIYers who tackle occasional metal cutting projects, such as building a metal shelf, repairing a fence, or cutting metal brackets. Users praise it for its ease of use, consistent cutting action, and affordable price point, which allows them to keep multiple blades on hand without breaking the bank.

Another option from Black & Decker is the Black & Decker 74-667 4-1/2-Inch by 5/8-Inch Metal Cutting Wheel, designed for grinders with a 5/8-inch arbor. This blade is also made from aluminum oxide and has a maximum RPM of 11,000, making it suitable for light to medium-duty cutting tasks. Its 0.062-inch thickness provides stability, and its reinforced construction ensures safety during use. The 74-667 is a popular choice among homeowners who have older grinders with smaller arbors and need a reliable blade for occasional metal cutting jobs, such as cutting rebar for a home improvement project or trimming metal flashing.

Black & Decker also offers a multi-purpose blade, the Black & Decker 74-670 4-1/2-Inch Multi-Material Cutting Wheel, which can cut through metal, as well as wood and plastic, making it a versatile option for DIYers who work with multiple materials. This blade features a blend of abrasives that work effectively on metal, and its reinforced backing ensures durability across different materials. While it may not be as specialized as metal-only blades, it is a convenient choice for users who want a single blade that can handle a variety of tasks, saving space in their toolbox and reducing the need to switch blades frequently.

Lenox: High-Performance Blades for Demanding Cuts

Lenox, a brand with a long history of producing cutting tools, offers 4 1/2 angle grinder metal cutting blades that are designed for high performance and durability, particularly in demanding applications. Their Lenox 20582 4-1/2-Inch by 7/8-Inch Metal Cutting Wheel is a premium abrasive blade made from zirconia alumina, known for its aggressive cutting action and long lifespan. The 7/8-inch arbor and maximum RPM of 13,300 make it compatible with most professional-grade grinders, and its reinforced fiberglass backing provides added strength and safety.

The 20582 features a unique “T2 Technology” that enhances the blade’s ability to resist wear and maintain sharpness, even when cutting through thick or hardened steel. Its thin profile (0.045 inches) allows for fast, precise cuts, making it ideal for cutting metal studs, conduit, and structural steel in construction and fabrication settings. The blade’s design minimizes sparking, which is a benefit for worksites where fire hazards are a concern, and its balanced construction reduces vibration, reducing user fatigue during long work sessions. Professionals who have used the 20582 praise its consistency, noting that it cuts through metal with ease and lasts longer than many competing blades, making it a cost-effective choice in the long run.

For cutting stainless steel, Lenox offers the Lenox 20583 4-1/2-Inch by 7/8-Inch Stainless Steel Cutting Wheel. This blade is formulated with a specialized abrasive blend that is designed to cut through stainless steel without causing contamination or excessive heat, which can lead to discoloration or warping. The blade’s thin profile (0.045 inches) reduces friction and heat buildup, and its reinforced backing ensures durability even when cutting through thick stainless steel sheets or pipes. The 20583 has a maximum RPM of 13,300 and a 7/8-inch arbor, making it compatible with standard grinders, and its aggressive cutting action allows for efficient material removal, saving time on the job. This blade is a favorite among metalworkers who specialize in stainless steel fabrication, as it produces clean, precise cuts that require minimal post-processing.

Lenox also offers a carbide-tipped blade, the Lenox 20590 4-1/2-Inch Carbide Tipped Metal Cutting Blade, which features carbide teeth designed for fast, clean cuts on a variety of metals, including steel, aluminum, and copper. The 7/8-inch arbor and maximum RPM of 12,000 make it suitable for use with most 4 1/2 angle grinders, and its 0.090-inch thickness provides stability for cutting through thicker materials. The carbide teeth are engineered to stay sharp longer than abrasive blades, making this blade a cost-effective choice for users who cut metal frequently. The blade’s tooth geometry is optimized for efficient chip removal, reducing heat and preventing clogging, and its anti-vibration design ensures smooth operation, even during extended use.

Walter Surface Technologies: Industrial-Grade Blades for Heavy-Duty Use

Walter Surface Technologies, a leader in surface treatment and metalworking solutions, offers 4 1/2 angle grinder metal cutting blades that are designed for industrial-grade performance, suitable for heavy-duty cutting tasks in manufacturing, fabrication, and construction. One of their standout models is the Walter 50048 4-1/2-Inch by 7/8-Inch Metal Cutting Wheel. This abrasive blade is made from a high-performance zirconia alumina blend that is engineered for fast cutting and long life on ferrous metals, including carbon steel, alloy steel, and cast iron. The 7/8-inch arbor and maximum RPM of 13,300 make it compatible with high-speed industrial grinders, and its reinforced fiberglass backing meets strict safety standards for heavy use.

The 50048 features a unique “Zirconia Plus” formulation that enhances the blade’s cutting efficiency, allowing it to remove material quickly while maintaining a cool cutting temperature, reducing the risk of warping the workpiece. Its thin profile (0.045 inches) allows for precise cuts, making it ideal for cutting thick steel plates, structural beams, and heavy-walled pipes. The blade’s design ensures minimal vibration, which is crucial for operators who use grinders for hours at a time, and its consistent performance reduces downtime due to blade changes. Industrial users praise the 50048 for its durability, noting that it outlasts many other blades when used continuously on tough metals, making it a cost-effective choice for high-volume production environments.

For cutting stainless steel, Walter offers the Walter 50050 4-1/2-Inch by 7/8-Inch Stainless Steel Cutting Wheel. This specialized blade is formulated with a low-chloride, low-sulfur abrasive blend that prevents contamination of stainless steel, which is critical for applications where the metal’s corrosion resistance must be maintained. The blade’s thin profile (0.045 inches) reduces heat buildup, preventing work hardening of the stainless steel, and its reinforced backing ensures durability even when cutting through thick or hardened stainless steel. The 50050 has a maximum RPM of 13,300 and a 7/8-inch arbor, making it compatible with standard grinders, and its aggressive cutting action allows for efficient material removal, saving time in industrial settings. This blade is a top choice for manufacturers of stainless steel equipment, such as food processing machinery and medical devices, where precision and material integrity are paramount.

Walter also offers a diamond blade, the Walter 88064 4-1/2-Inch Diamond Metal Cutting Blade, designed for cutting the hardest metals, including tool steel, hardened steel, and cast iron. This blade features a continuous rim with high-density diamond segments that are bonded to a steel core using a high-temperature process, ensuring exceptional durability and long life. The 7/8-inch arbor and maximum RPM of 13,300 make it compatible with most grinders, and its thin kerf (0.080 inches) allows for precise cuts with minimal material waste. The diamond segments are designed to stay sharp even when cutting through the toughest materials, and the blade’s design allows for cool cutting, reducing the risk of damaging the workpiece. This blade is a favorite among industrial machinists and fabricators who need to make precise cuts on hard metals and want a blade that can handle the demands of heavy-duty use.

Klingspor: Precision Abrasives for Metalworking

Klingspor, a German manufacturer of abrasives, offers 4 1/2 angle grinder metal cutting blades that are known for their precision and consistency, making them popular among metalworkers who demand high-quality results. Their Klingspor 361550 4-1/2-Inch by 7/8-Inch Metal Cutting Wheel is an abrasive blade made from zirconia alumina, designed for fast, clean cuts on ferrous metals. The 7/8-inch arbor and maximum RPM of 13,200 make it compatible with most standard grinders, and its reinforced fiberglass backing provides safety and durability.

The 361550 features a uniform grain distribution that ensures consistent cutting performance throughout the blade’s lifespan, reducing the risk of uneven cuts or sudden wear. Its thin profile (0.045 inches) allows for precise cuts, making it ideal for intricate metalworking tasks, such as cutting metal sheets for fabrication or trimming metal parts to size. The blade’s design minimizes heat buildup, which is important for preventing warping in thin metals, and its balanced construction reduces vibration, making it comfortable to use for extended periods. Metalworkers appreciate the 361550 for its reliability and ability to produce smooth, burr-free cuts, which reduces the need for post-cutting finishing and improves overall productivity.

For cutting non-ferrous metals, Klingspor offers the Klingspor 361560 4-1/2-Inch by 7/8-Inch Non-Ferrous Cutting Wheel. This blade is formulated with silicon carbide, an abrasive that is effective on aluminum, copper, brass, and other soft metals, as it resists clogging and reduces heat buildup. The 7/8-inch arbor and maximum RPM of 13,200 make it compatible with standard grinders, and its reinforced backing ensures durability. The blade’s thin profile (0.045 inches) allows for precise cuts, making it ideal for cutting aluminum tubing, copper pipes, and brass fittings. Users praise it for its ability to produce clean, smooth cuts on non-ferrous metals without causing excessive burring or deformation, which is important for projects where the appearance and dimensional accuracy of the cut are critical.

Klingspor also offers a diamond blade, the Klingspor 362550 4-1/2-Inch Diamond Metal Cutting Blade, designed for cutting hard metals like stainless steel, cast iron, and hardened steel. This blade features a continuous rim with high-quality diamonds embedded in a metal matrix, ensuring long life and consistent performance. The 7/8-inch arbor and maximum RPM of 13,200 make it compatible with most grinders, and its thin kerf (0.078 inches) allows for precise cuts with minimal material loss. The diamond rim is designed to cut through hard metals with ease, and the blade’s design allows for cool cutting, reducing the risk of warping or damaging the workpiece. This blade is a top choice for metalworkers who specialize in cutting hard metals and want a blade that delivers precise, consistent results.

Norton: Trusted Performance in Abrasive Blades

Norton, a brand with over 130 years of experience in abrasives, offers 4 1/2 angle grinder metal cutting blades that are trusted by professionals for their performance and reliability. One of their most popular models is the Norton 66252542068 4-1/2-Inch by 7/8-Inch Metal Cutting Wheel. This abrasive blade is made from zirconia alumina, a high-performance abrasive that provides fast cutting and long life on ferrous metals. The 7/8-inch arbor and maximum RPM of 13,300 make it compatible with most professional-grade grinders, and its reinforced fiberglass backing provides added strength and safety.

The 66252542068 features Norton’s proprietary “VIPER” ceramic alumina abrasive, which is designed to self-sharpen during use, maintaining cutting efficiency throughout the blade’s lifespan. Its thin profile (0.045 inches) allows for quick, precise cuts, making it ideal for cutting metal studs, conduit, and sheet metal. The blade’s design minimizes vibration, reducing user fatigue, and its balanced construction ensures smooth operation, even at high speeds. Users praise this blade for its consistent performance, even when cutting through thick or hardened steel, and its ability to produce clean cuts with minimal sparking, which is a plus for worksites with strict safety regulations.

For cutting stainless steel, Norton offers the Norton 66252542070 4-1/2-Inch by 7/8-Inch Stainless Steel Cutting Wheel. This specialized blade is formulated with a chrome oxide abrasive that is gentle on stainless steel, reducing the risk of contamination and ensuring clean cuts. The blade has a maximum RPM of 13,300 and a 7/8-inch arbor, making it compatible with standard grinders, and its thin profile (0.045 inches) minimizes heat buildup, preventing work hardening of the stainless steel. The reinforced backing ensures durability, and the blade’s aggressive cutting action allows for efficient material removal, making it a favorite among metalworkers who specialize in stainless steel fabrication.

Norton also offers a carbide-tipped blade, the Norton 66252542100 4-1/2-Inch Carbide Tipped Metal Cutting Blade, which features carbide teeth designed for fast, clean cuts on a variety of metals, including steel, aluminum, and copper. The 7/8-inch arbor and maximum RPM of 12,000 make it suitable for use with most 4 1/2 angle grinders, and its 0.090-inch thickness provides stability for cutting through thicker materials. The carbide teeth are engineered to stay sharp longer than abrasive blades, making this blade a cost-effective choice for users who cut metal frequently. The blade’s tooth geometry is optimized for efficient chip removal, reducing heat and preventing clogging, and its anti-vibration design ensures smooth operation.

Conclusion: Choosing the Right 4 1/2 Angle Grinder Metal Cutting Blade

Choosing the right 4 1/2 angle grinder metal cutting blade depends on a variety of factors, including the type of metal being cut, the desired cut quality, the frequency of use, and the grinder’s specifications. Abrasive blades, such as those made from zirconia alumina, are ideal for general-purpose cutting of ferrous metals and offer a good balance of performance and affordability. Specialized blades, like those designed for stainless steel or non-ferrous metals, provide better results when working with specific materials, preventing contamination, heat buildup, and excessive wear. Diamond-tipped and carbide-tipped blades, while more expensive, offer superior durability and performance for cutting hard metals,making them a worthwhile investment for professionals who frequently tackle tough cutting tasks.

When selecting a blade, it is crucial to match the arbor size with the grinder’s spindle to ensure a secure fit, as a loose blade can be dangerous and cause uneven cuts. Additionally, always check the blade’s maximum RPM rating to ensure it exceeds or matches the grinder’s maximum speed—using a blade with a lower RPM rating is a serious safety hazard that can lead to blade disintegration. The blade’s thickness and kerf should also be considered based on the material thickness and the desired precision: thinner blades are better for precise cuts and fast material removal, while thicker blades offer more stability for cutting through heavy-duty metals.

For DIY enthusiasts and occasional users, brands like Black & Decker offer affordable aluminum oxide blades that provide reliable performance for light to medium-duty tasks, such as cutting mild steel pipes or sheet metal for home projects. These blades balance cost and functionality, making them accessible for those who don’t need industrial-grade durability.

Professionals in construction, fabrication, and metalworking will benefit from premium options from DEWALT, Makita, Bosch, and Milwaukee, which offer zirconia alumina blades with reinforced backings, aggressive cutting action, and long lifespans. These blades are designed to withstand continuous use on tough metals like structural steel and rebar, delivering consistent results and minimizing downtime for blade changes.

When working with stainless steel, specialized blades from Lenox, Walter Surface Technologies, and Norton are engineered to prevent contamination and heat-related damage, ensuring clean cuts that meet strict quality standards. These blades are essential for industries like food processing, medical equipment manufacturing, and architectural metalwork, where the integrity of the stainless steel is paramount.

For cutting non-ferrous metals such as aluminum, copper, and brass, blades from Makita, Ingersoll Rand, and Klingspor, formulated with silicon carbide, resist clogging and reduce heat buildup, producing smooth, burr-free cuts. These blades are ideal for automotive work, plumbing, and electronics manufacturing, where precision and material finish are critical.

Diamond-tipped blades from DEWALT, Makita, Milwaukee, and Walter Surface Technologies are the top choice for cutting the hardest metals, including cast iron, hardened steel, and tool steel. Their exceptional durability—often lasting 50 times longer than abrasive blades—makes them cost-effective for high-volume industrial use, where frequent blade replacements would otherwise slow down production.

In summary, the 4 1/2 angle grinder metal cutting blade market offers a diverse range of options to suit every need and budget. By understanding the specific requirements of your project—material type, cut precision, and usage frequency—you can select a blade that not only enhances performance but also ensures safety and efficiency. Whether you’re a DIYer working on a weekend project or a professional fabricator managing daily industrial tasks, investing in the right blade will make your metal cutting work faster, easier, and more reliable, ultimately leading to better results and greater productivity. Always remember to follow safety guidelines, including wearing appropriate protective gear (safety glasses, gloves, and hearing protection) and inspecting blades for damage before use, to ensure a safe and successful cutting experience.