Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

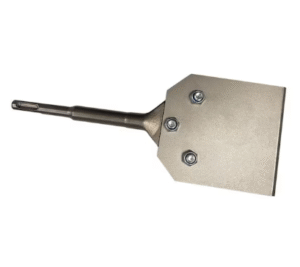

Scraper drill bits, as critical components in coal mining and rock drilling, are designed to efficiently break and remove rock or coal strata during excavation. Their performance directly impacts mining efficiency, safety, and cost-effectiveness. The blade geometry of these drill bits, including parameters such as blade angle, width, thickness, and curvature, plays a pivotal role in determining their adaptability to different geological formations. This paper explores the intricate relationship between blade geometry and formation adaptation, analyzing how specific design features influence cutting efficiency, wear resistance, and overall operational performance in diverse mining environments.

The blade geometry of scraper drill bits encompasses several key parameters that collectively define their cutting behavior and interaction with the formation. These parameters include:

The helix angle refers to the inclination of the blade relative to the central axis of the drill bit. It influences the cutting force distribution, chip evacuation, and the bit’s ability to penetrate hard strata. A steeper helix angle (e.g., 20°–30°) enhances cutting efficiency in soft to medium-hard formations by promoting faster chip removal and reducing cutting resistance. Conversely, a shallower helix angle (e.g., 10°–15°) is more suitable for hard rock formations, as it provides greater structural strength and reduces the risk of blade breakage under high stress.

Blade width determines the contact area between the bit and the formation, affecting the cutting load and wear rate. Wider blades distribute the cutting force over a larger area, reducing specific pressure and extending bit life in abrasive formations. However, excessive width may increase cutting resistance and reduce penetration rate. Blade thickness, on the other hand, influences the bit’s structural integrity and resistance to bending or fracturing. Thicker blades are more robust but may reduce cutting efficiency in soft formations due to increased inertia.

The curvature of the blade, whether convex, concave, or flat, affects the cutting mechanism and chip formation. Convex blades generate a scooping action, facilitating chip removal and reducing clogging in soft formations. Concave blades, while less common, may enhance cutting precision in specific applications. Flat blades offer a balance between cutting efficiency and structural strength, making them versatile for mixed formations. Additionally, the shape of the blade tip (e.g., pointed, rounded, or chisel-shaped) influences the bit’s ability to initiate cutting and penetrate hard strata.

The number of blades and their spatial arrangement on the drill bit affect the cutting load distribution and vibration characteristics. Multi-blade bits (e.g., 3–6 blades) distribute the cutting force more evenly, reducing wear on individual blades and improving stability in hard or uneven formations. However, an excessive number of blades may increase cutting resistance and reduce penetration rate. The arrangement of blades, whether symmetrical or asymmetrical, also influences the bit’s balance and cutting dynamics.

The geological formation being drilled is a primary determinant of the optimal blade geometry for scraper drill bits. Different formations exhibit unique physical and mechanical properties, such as hardness, abrasiveness, fracture toughness, and bedding structure, which necessitate tailored bit designs for optimal performance. The following sections discuss the relationship between blade geometry and formation adaptation in common mining environments.

Soft formations, characterized by low hardness and high plasticity, require drill bits with geometries that promote fast penetration and efficient chip removal. Key considerations include:

Example Brands and Models:

Medium-hard formations, with moderate hardness and fracture toughness, require drill bits that balance cutting efficiency with durability. Key considerations include:

Example Brands and Models:

Hard formations, characterized by high hardness and fracture toughness, demand drill bits with geometries that prioritize structural strength and wear resistance. Key considerations include:

Example Brands and Models:

Abrasive formations, containing high concentrations of hard minerals like quartz, cause rapid wear on drill bits. Blades in such environments must be designed to resist abrasion while maintaining cutting efficiency. Key considerations include:

Example Brands and Models:

In addition to standard blade geometries tailored to specific formation types, advanced designs have emerged to address specialized mining challenges. These innovations leverage cutting-edge materials, manufacturing techniques, and computational simulations to optimize blade performance in extreme conditions.

Self-sharpening blades, achieved through strategic placement of hard inserts or wear-resistant coatings, maintain cutting efficiency by continuously exposing fresh cutting edges as the bit wears. This design reduces the need for frequent bit changes, improving operational continuity and reducing downtime.

Example:

Variable geometry blades, featuring adjustable angles or widths, adapt dynamically to changing formation properties during drilling. This flexibility allows a single bit to perform optimally across multiple strata, reducing the need for bit changes and enhancing operational efficiency.

Example:

3D printing technology enables the fabrication of complex blade geometries that are difficult or impossible to produce using traditional manufacturing methods. These custom designs can be tailored to specific formation properties, optimizing cutting efficiency and wear resistance.

Example:

The development of advanced computational tools, such as finite element analysis (FEA) and discrete element method (DEM) simulations, has revolutionized the design and optimization of scraper drill bit blade geometries. These simulations allow engineers to model the interaction between the bit and the formation, predicting cutting forces, wear patterns, and vibration characteristics under various operating conditions.

FEA simulations analyze the stress and strain distribution within the drill bit during cutting, identifying potential failure points and optimizing blade geometry for structural integrity. By simulating different blade angles, widths, and thicknesses, engineers can determine the optimal design for a given formation.

Example Application:

DEM simulations model the interaction between the drill bit and the formation at the particle level, providing insights into chip formation, wear mechanisms, and cutting efficiency. By simulating different blade geometries and formation properties, engineers can identify the most effective design for a specific application.

Example Application:

Multi-objective optimization algorithms, such as genetic algorithms or particle swarm optimization, are used to identify the optimal blade geometry that balances multiple performance metrics, such as cutting efficiency, wear resistance, and vibration reduction. These algorithms evaluate thousands of potential designs, selecting the one that best meets the specified criteria.

Example Application:

Real-world case studies provide valuable insights into the practical application of blade geometry optimization in mining operations. The following examples illustrate how tailored blade designs have improved performance in specific formation types.

A coal mining operation in a soft seam faced challenges with bit balling and low penetration rates using standard drill bits. By switching to a bit with a high helix angle (25°), wide blades (60 mm), and a convex curvature, the operation achieved a 30% increase in penetration rate and a 50% reduction in bit changes due to balling.

Bit Model: Joy Global (Komatsu Mining) PFC-250

A limestone quarry experienced excessive wear and short bit life when using standard drill bits in medium-hard rock. By adopting a bit with a moderate helix angle (18°), medium blade width (50 mm), and a flat curvature, the quarry achieved a 20% increase in bit life and a 15% reduction in drilling costs.

Bit Model: Atlas Copco Secoroc RC-180

A granite drilling project required high penetration rates in extremely hard rock. By using a bit with a low helix angle (12°), narrow and thick blades (40 mm width, 20 mm thickness), and chisel-shaped tips, the project achieved a 25% increase in penetration rate and a 30% reduction in bit consumption compared to standard designs.

Bit Model: Boart Longyear LF-120

The future of blade geometry design for scraper drill bits is shaped by advancements in materials science, manufacturing technology, and computational modeling. Key trends include:

The integration of smart sensors and IoT (Internet of Things) technology into drill bits will enable real-time monitoring of blade wear, cutting forces, and vibration characteristics. This data can be used to dynamically adjust drilling parameters or trigger bit changes, optimizing performance and reducing downtime.

Nanostructured materials, such as nanocrystalline alloys or carbon nanotube-reinforced composites, offer superior hardness, toughness, and wear resistance compared to traditional materials. These materials will enable the development of blades that can withstand extreme conditions while maintaining cutting efficiency.

Additive manufacturing, or 3D printing, will continue to evolve, enabling the production of blade geometries with unprecedented complexity and precision. This technology will allow for the customization of blades to specific formation properties, further optimizing performance and reducing costs.

Artificial intelligence (AI) and machine learning (ML) algorithms will play an increasingly important role in blade geometry optimization. By analyzing vast amounts of data from simulations and real-world operations, these algorithms can identify patterns and correlations that human engineers may overlook, leading to breakthroughs in blade design.

The relationship between blade geometry and formation adaptation in scraper drill bits is a complex and multifaceted topic that has significant implications for mining efficiency, safety, and cost-effectiveness. By understanding the influence of blade parameters such as helix angle, width, thickness, and curvature on cutting performance, engineers can design bits that are tailored to specific formation types, optimizing performance and extending bit life. Advanced computational tools, such as FEA and DEM simulations, along with multi-objective optimization algorithms, further enhance the design process, enabling the identification of optimal blade geometries that balance multiple performance metrics. Real-world case studies demonstrate the practical benefits of blade geometry optimization, while future trends, such as smart sensors, nanostructured materials, additive manufacturing, and AI-driven design, promise to revolutionize the field of scraper drill bit technology. As mining operations continue to face challenges posed by diverse and complex geological formations, the development of innovative blade geometries will remain a critical area of research and development, driving improvements in efficiency, safety, and sustainability.